DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>Installation of 3 sets of Semi-Continuous Waste Tire Pyrolysis Equipment in Brazil

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>Installation of 3 sets of Semi-Continuous Waste Tire Pyrolysis Equipment in Brazil

In December 2024, we successfully completed the installation and commissioning of three sets of semi-continuous waste tire pyrolysis equipment. This waste tire recycling pyrolysis project, located in Brazil, had outstanding performance of equipment efficiency and stability.

Clik the installation video of 3 sets of semi-continuous waste tire pyrolysis equipment for more details:

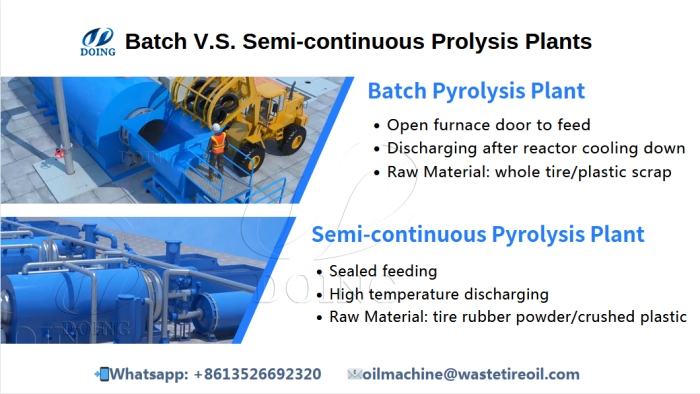

The client is a company with some experience in the waste tire recycling industry, previously operating a batch type pyrolysis equipment. They faced production capacity and efficiency bottlenecks when they had bigger amount of waste tires for recycling. After conducting an evaluation, the client decided to upgrade their equipment to improve production efficiency and economic performance.

Comparisions of batch and semi-continuous pyrolysis equipment

Comparisions of batch and semi-continuous pyrolysis equipment

The client prioritized the following points:

Equipment Efficiency: Improve production efficiency, reduce energy consumption, and lower labor costs.

Factory Production Expertise: Ensure equipment safety, stability, and ease of operation.

After-Sales Service Assurance: Long-term maintenance and technical support for the equipment were key factors in the client's decision-making process.

1. Consultation and Confirmation:

In March 2024, the Brazil client learned about our company and equipment through multiple channels. They were particularly interested in our DOING semi-continuous waste tire pyrolysis technology, which has higher processing efficiency than batch pyrolysis plant and costs less than fully continuous waste tire pyrolysis equipment. After several rounds of technical discussions and adjustments to the plan, the client was satisfied with the proposed equipment solution and officially confirmed the collaboration in early April 2024.

2. Equipment Production and Shipping:

As per the contract, we completed the production of three sets of semi-continuous waste tire pyrolysis equipment in July 2024 and shipped them to Brazil on schedule. The equipment underwent rigorous quality checks to ensure its stability and high performance.

Semi-continuous waste tire pyrolysis equipmeny delivered to Brazil

Semi-continuous waste tire pyrolysis equipmeny delivered to Brazil

3. Installation and Commissioning:

In mid-December 2024, our technical team successfully arrived in Brazil and completed the installation and commissioning of the waste tire pyrolysis equipment as planned. To ensure the pyrolysis units operated efficiently and stably, our engineers worked closely with the client to solve various local technical issues and ensure smooth operations.

The successful installation of these 3 sets of semi-continuous waste tire pyrolysis equipment in Brazil demonstrates our technical advantages and market competitiveness in the waste tire recycling industry.

Semi-continuous pyrolysis equipment installed in Brazil

Semi-continuous pyrolysis equipment installed in Brazil

We look forward to collaborating with more clients to drive the sustainable development of the waste tire recycling pyrolysis industry. If you have any requirements for our waste tire equipment and one-stop technical services, please feel free to contact us.