DOING HOLDINGS

DOING HOLDINGS

Choosing the right pyrolysis equipment with the suitable capacity involves key considerations of feedstock type, feedstock quantity and output to ensure it meets your specific needs and operational requirements.

Depended on the input amount and situation of raw materials, I will introduce our DOING pyrolysis equipment with different capacities to you:

For small capacity, we have batch type pyrolysis equipment represented by frame type. We provide 100kg/day and 500kg/day skid-mounted pyrolysis equipment for customers for two purposes. One is to test their solid waste, hazardous waste feedstocks, such as tire waste, plastic waste, aluminum plastic, oil sludge, medical waste, coal tar oil residue. Then they can know the oil yield from their feedstocks to calculate the profit of this business. The other is to prove the feasibility and environmental protection of this pyrolysis business to the government department for better applying permission for a bigger capacity pyrolysis equipment. If you want to start to do pyrolysis business from small scale, just like 100kg, 500kg, 1tpd, 5tpd and still don’t have so much experience, I suggest this batch type pyrolysis equipment to you.

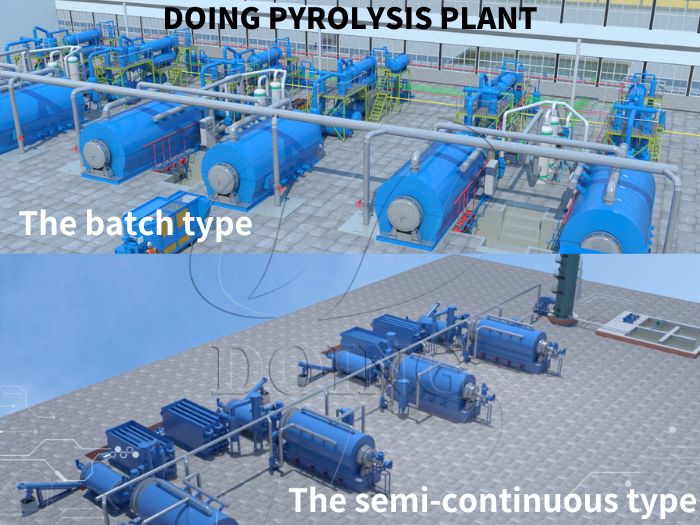

DOING batch type pyrolysis machine with different capacity

DOING batch type pyrolysis machine with different capacity

For middle capacity, we have 5tpd, 10tpd, 15tpd, 20tpd batch type pyrolysis equipment and semi-continuous pyrolysis equipment. If you want to earn money from this project at beginning, I suggest this batch type pyrolysis equipment and semi-continuous pyrolysis equipment to you. Batch type pyrolysis equipment needs to continuously input whole pieces of feedstocks and remove waste residues, and the production efficiency is one furnace per day. Semi-continuous equipment inputs waste fragments and runs uninterruptedly. The operating efficiency is higher than that of batch type pyrolysis equipment, and the price is also higher. But for special wastes such as aluminum plastics and hazardous wastes, the products are in block form, which is more suitable for the slagging system of intermittent pyrolysis equipment, and customers can easily operate and maintain the entire equipment.

DOING batch pyrolysis equipment and semi-continuous pyrolysis equipment

DOING batch pyrolysis equipment and semi-continuous pyrolysis equipment

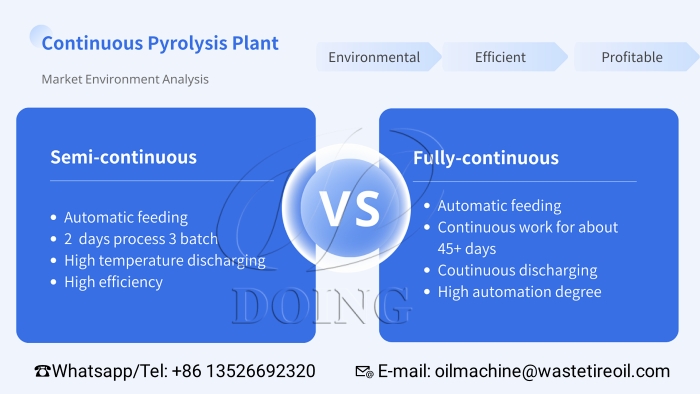

For large capacity, we have semi-continuous pyrolysis equipment and fully continuous pyrolysis equipment. We recommend semi-continuous pyrolysis equipment to customer who want to expand production and improve efficiency but have limited budgets. The semi-continuous pyrolysis equipment is designed by combining the process of fully-continuous and batch pyrolysis equipment which adopts a screw conveyor system, which can effectively improve production efficiency, save cooling time and achieve the production efficiency of three batches in two days. We recommend fully continuous pyrolysis equipment with PLC system to customers who have experience in batch type pyrolysis equipment and semi-continuous pyrolysis equipment and want to expand their productionand processing lines, just like 30tpd, 50tpd and . It runs for 24 hours and can run continuously for about 30-40 days, greatly improving production efficiency and reducing labor cost.

DOING semi-continuous pyrolysis equipment and fully-continuous pyrolysis equipment

DOING semi-continuous pyrolysis equipment and fully-continuous pyrolysis equipment

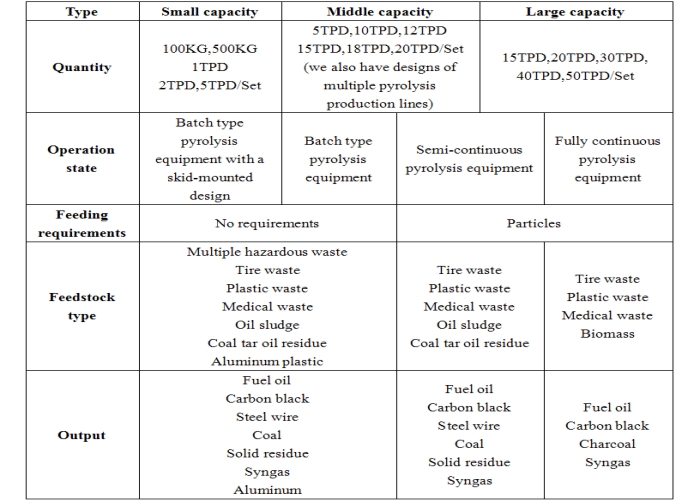

Here is a table to give you a clearer idea of the suitable capacity of pyrolysis equipment and its suitability:

Table of the suitable capacity of pyrolysis equipment and its suitability

Table of the suitable capacity of pyrolysis equipment and its suitability

If you require DOING pyrolysis equipment or want to customize suitable capacities of pyrolysis production lines, you can find us to obtain more report documents. We will help you to start this business and provide perfect service with you.