DOING HOLDINGS

DOING HOLDINGS

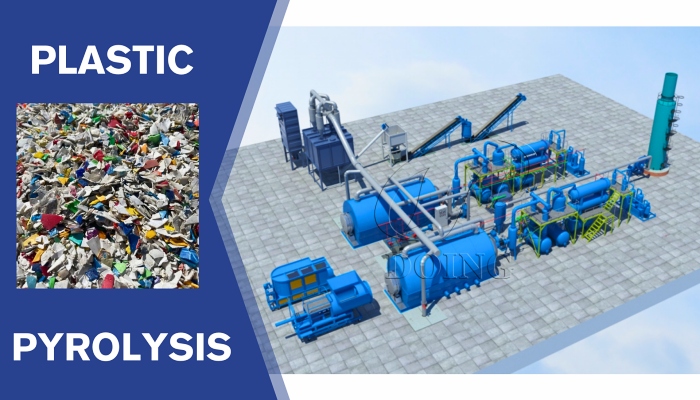

For the disposal and reuse of waste plastics, plastic oil pyrolysis plant has become a popular and green solution to turn waste plastic into useful products. Here DOING can provide a customization scheme for plastic oil pyrolysis plant based on your requirements.

DOING plastic oil pyrolysis plant for sale

DOING plastic oil pyrolysis plant for sale

The following is a brief introduction about the customization scheme for the whole plastic oil pyrolysis plant production line:

1. Waste plastic pretreatment equipment

(1) Crushing equipment

If the DOING batch plastic oil pyrolysis plant is chosen, which has no strict requirements for the feeding waste plastics, it is not necessary to use crushing equipment. Bundled or loose plastic can be fed directly.

However, if a DOING semi-continuous or fully continuous plastic oil pyrolysis plant is chosen, the plastic needs to be broken first and broken into small pieces of 30-50 mm.

DOING waste plastic crushing equipment

DOING waste plastic crushing equipment

(2) Sorting equipment

The DOING continuous plastic oil pyrolysis plant requires that the raw material does not contain hard solids such as metals and stones, so DOING can provide magnetic separators, electric separators, etc. for simple separation to pyrolysis waste plastics.

2. Plastic oil pyrolysis plant

(1) Different types

For plastic oil pyrolysis plant, DOING can provide three types for you: batch type, semi-continuous type and fully continuous type, which have different capacities for your reference. Of course, DOING can provide a customization scheme based on your processed plastic capacity and investment scale.

Three types of DOING plastic oil pyrolysis plant

Three types of DOING plastic oil pyrolysis plant

(2) Different configurations

Generally, the common configurations of DOING plastic oil pyrolysis plant include the pyrolysis reactor, cooling system, which also have different customization schemes. Take the main part - pyrolysis reactor as an example, we can provide different materials for manufacturing, such as Q345R, Q245R, stainless steel. For the cooling system, we can provide two schemes of tube condensation system and water tank cooling system, which have different advantages to meet your demands.

DOING tube condensation system for sale

DOING tube condensation system for sale

And in addition to the common configurations, if you want to get better work performance, there are also other optional configurations for your choice.

Wax removal device: As we all know, PP plastic has the highest oil yield, but it is also the most serious plastic wax formation. To enhance the whole work performance of the plastic oil pyrolysis plant and decrease the cleaning time for the pyrolysis equipment, DOING can provide some wax removal solutions for our customers, such as special wax removal structure and catalyst tower device.

Wax removal device of DOING plastic oil pyrolysis plant

Wax removal device of DOING plastic oil pyrolysis plant

Environmental protection device: For different countries have different standards on environmental protection, DOING can provide different levels of environmental protection devices based on their demands, such as the tail-gas cleaning system, desulfurization tower, carbon black wind transfer system, etc.

DOING pyrolysis plant projects display

DOING pyrolysis plant projects display

DOING plastic oil pyrolysis plant has been put into operation in many countries, such as Japan, Russia, Kazakhstan, China, Vietnam, Thailand, India, Sri Lanka, Mexico, Brazil, etc. During the cooperation with these customers, they all were satisfied with the customization scheme for plastic oil pyrolysis plant provided by DOING. If you are also interested in our plastic oil pyrolysis plant, just feel free to contact us directly!