DOING HOLDINGS

DOING HOLDINGS

Pyrolysis equipment configuration significantly impacts operational efficiency, scalability, and ROI. As a leading pyrolysis equipment manufacturer, DOING provides tailored solutions ranging from skid-mounted systems to full production lines. This article explores two primary setups: skid-mounted pyrolysis equipment (modular designs) and complete pyrolysis plants, helping clients select optimal configurations.

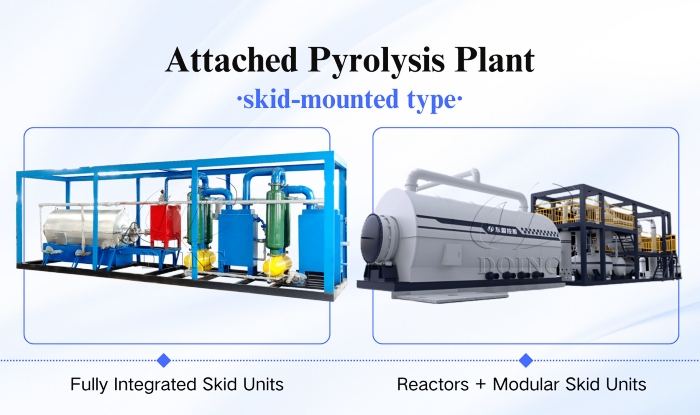

Option 1: Skid-Mounted Pyrolysis Equipment

DOING’s skid-mounted pyrolysis systems feature pre-assembled components for quick deployment. Ideal for small-scale projects, research trials, or feasibility studies, they come in two types:

DOING skid-mounted pyrolysis equipment for sale

DOING skid-mounted pyrolysis equipment for sale

A. Fully Integrated Skid Units

Capacity: 100–500kg/day

All equipment (reactor, condenser, buffer tanks) mounted on a single frame.

Advantages: Compact, budget-friendly, plug-and-play operation.

B. Pyrolysis Reactors + Modular Skid Units

Core pyrolysis reactor paired with skid-mounted auxiliary systems (condensation, gas scrubbing).

Advantages: Minimal on-site assembly, scalable for pilot projects.

Low upfront investment

Easy relocation and maintenance

Ideal for startups or testing phases

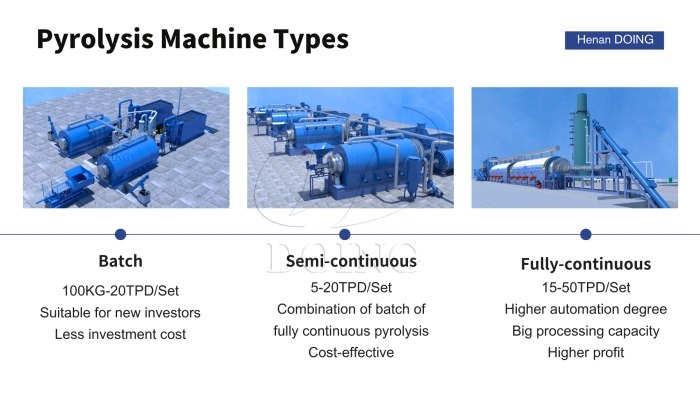

Option 2: Complete Pyrolysis Machine Production Lines

For large-scale industrial projects (1–50 tons/day), DOING offers fully customized plants with three operational modes:

Three types of pyrolysis equipment production lines

Three types of pyrolysis equipment production lines

Batch Pyrolysis Machine: Manual feeding/discharging, lower automation.

Semi-Continuous Pyrolysis Machine: Partial automation for steady output.

Fully Continuous Pyrolysis Machine: Fully automated, 24/7 operation.

Pyrolysis Equipment Configuration Includes:

| Standard | Optional |

| Pyrolysis Reactors with temperature control | Pre-treatment systems (shredding, cutting) |

| Condensation and oil collection units | Feed hoppers |

| Emission treatment (scrubbers, dust removal) | PLC control systems |

High throughput and automation

Consistent product quality

Reduced labor costs

Factors Influencing Pyrolysis Equipment Configuration Choices

Processing Capacity: Skid units suit<1TPD; full plants excel at 1–50TPD.

Budget Constraints: Skid systems minimize initial costs; full plants optimize long-term ROI.

Automation Needs: Continuous plants maximize efficiency; skid units allow manual oversight.

Space Limitations: Skid-mounted designs save floor space versus sprawling production lines.

DOING's pyrolysis equipment solutions adapt to diverse needs: skid-mounted systems deliver affordability for trials/small batches, while complete plants ensure industrial-scale productivity. With customizable batch, semi-continuous, or fully continuous modes, we provide end-to-end pyrolysis equipment for startups, labs, and large enterprises.

Ready to optimize your waste to fuel oil pyrolysis project? Contact DOING for tailored configurations and free technical support!