DOING HOLDINGS

DOING HOLDINGS

Home>News>Industry news>How much oil can be extracted from one ton of waste tires? You need to know the oil output ratio of waste tire refining!

Home>News>Industry news>How much oil can be extracted from one ton of waste tires? You need to know the oil output ratio of waste tire refining!

How much oil can be extracted from one ton of waste tires? Do you know the oil output ratio of waste tire refining? Under normal circumstances, 400-450 kg of fuel can be extracted from one ton of waste tires, which means that the oil yield of waste tires is about 45%, which is also determined by the fact that tires contain about 50% natural rubber and synthetic rubber. And rubber is a kind of petroleum product. Under the action of anaerobic and high-temperature cracking, the polymers with unsaturated bonds in the main chain of the rubber are broken, and the products are mainly monomers, dimers and fragments, and the products are repolymerized into various olefins to extract oil.

tire type and its oil yield

tire type and its oil yield

Of course, the above values are only for reference, because the amount of rubber contained in waste tires is a direct factor affecting the oil yield of waste tires. Therefore, different types of tires, different degrees of wear, and different amounts of rubber contained in them will lead to different oil yields from waste tire refining. For example: the oil output rate of large car tires, truck tires, and engineering tires is about 45-52%, while the oil output rate of car tires, motorcycle tires, and bicycle tires is about 35-40%. According to Dongying customer feedback, about 400-450 kg of fuel oil can be extracted from one ton of waste tires, and the oil yield of non-standard diesel oil from fuel oil is 80%-85%. After calculation, one ton of waste tires can also be refined 320-425 kg of non-standard diesel.

Waste tire refining process and its oil yield

Waste tire refining process and its oil yield

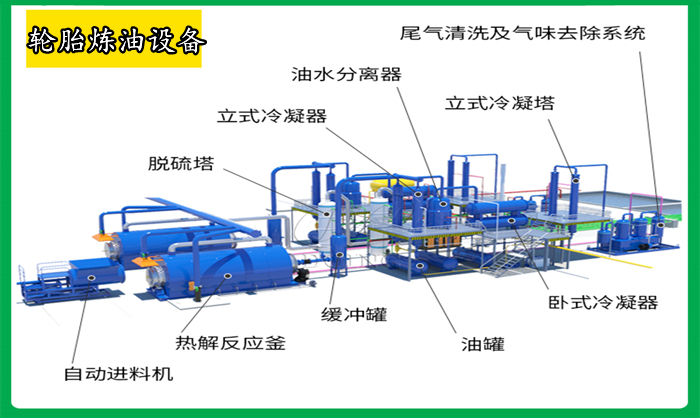

In addition to the oil yield of the tire itself, the amount of oil that can be extracted from a ton of waste tires is also closely related to the waste tire refining equipment. Although the oil yield of tires is about 45%, the equipment produced by some manufacturers on the market cannot meet such a standard, resulting in excessive loss during the oil refining process of waste tires, high residual oil content, and oil output from waste tire refining. low rate. Henan Dongying Company’s waste tire refining equipment is not only equipped with an accurate calculation system at the source to ensure that the tire feed is fully cracked and the oil output rate is high; it is also equipped with a three-stage condensation system in the middle link, so that the oil and gas produced by tire cracking enter the buffer tank one after another. The horizontal condenser, the tubular condenser and the condensation tower are fully cooled, and after exchanging heat with the condenser and circulating water, the oil is cooled into oil and then enters the oil storage tank, so that more oil can be extracted from one ton of waste tires.

Waste tire refining equipment

Waste tire refining equipment

Of course, the operation method and proficiency of workers in the waste tire refinery will also affect the oil output ratio of waste tires to a certain extent. Therefore, Dongying recommends that operating and production personnel must be trained first before taking up work. Henan Dongying Company provides one-stop service from product consultation, R&D and design, production and manufacturing to installation and commissioning, sales and after-sales "five in one". At the same time, it will provide free technical training for operating and production personnel to make them proficient in refining waste tires Equipment operating specifications and precautions.