DOING HOLDINGS

DOING HOLDINGS

Home>News>Industry news>What is the prospect of waste tire refining? Does waste tire refining really make money?

Home>News>Industry news>What is the prospect of waste tire refining? Does waste tire refining really make money?

After entering 2022, due to factors such as the economic downturn, the continuation of the epidemic, and geopolitics, the international energy tension has intensified, and the price of tire oil has also experienced a considerable increase due to this impact, from 3,000 yuan/ton at the beginning of the year to 4,800 yuan Yuan/ton, the waste tire refining industry has developed unprecedentedly, and the market prospect is very broad.

According to relevant data released by the China Rubber Industry Association, from 11.45 million tons in 2014 to 20 million tons in 2021, the average annual compound growth rate is about 5.3%. sufficient market resources. Waste tires themselves have high utilization value and are misplaced resources. The country has also introduced policies for comprehensive utilization of waste tires and tax rebate and subsidy policies to encourage the promotion of the sunrise industry of waste tire refining. With the good news such as the large volume of waste tires and low prices, the soaring tire oil, and the support of national policies, the market for oil refining of waste tires has broad prospects and good market conditions, which is worth investing in!

Scrap tires

Scrap tires

Many customers may still wonder: Is it true that waste tires are refined into oil? Does waste tire refining really make money? Dongying Xiaobian is here to tell you, first of all, waste tire refining is a real and running project. Many manufacturers at home and abroad have introduced waste tire refining equipment to centrally process a large number of waste tires. After years of technical iterations, waste Tire refining technology is quite mature. Secondly, waste tire refining is really profitable. Taking waste tire refining equipment with a daily processing capacity of 12 tons/day as an example, the raw materials and output are based on the maximum in December 2022 >New market price calculation, Dongying Company will analyze the investment cost and profit analysis of waste tire refining for everyone's reference.

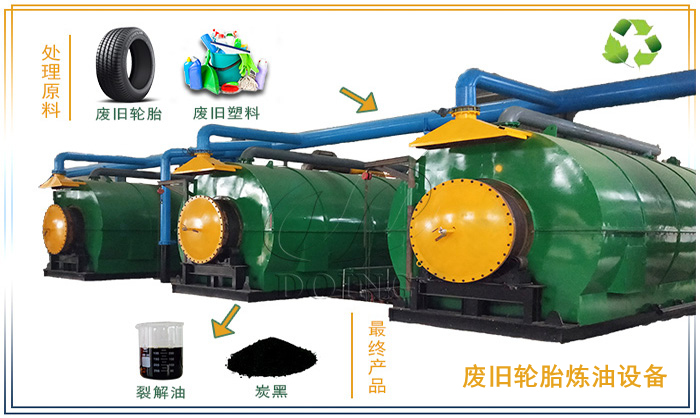

Waste tire refining equipment

Waste tire refining equipment

The proportion of products obtained after pyrolysis of 12 tons of waste tires is: tire pyrolysis oil 5.4 tons (oil yield 45%), carbon black 3.6 tons (extraction rate 30%), steel wire 1.2 tons (output rate 10%), combustible gas directly Recycled as fuel.

1) Cost

Waste tires: 12 tons*2000=24000 yuan

Heating fuel: 1,000 yuan (oil, gas, coal, wood, etc. can be used for initial heating. When the temperature of the refining furnace rises to 500°C and stable oil and gas production begins, the combustible gas produced by the refining furnace can be used for heating. Initial heating The cost incurred is calculated as 1,000 yuan);

Power consumption: 400 yuan (the operating power of 12 tons of waste tire refining equipment is 20Kw/h, and the cost of running for one day is about 400 yuan;

Water consumption: 0 yuan (water is recycled, a little evaporation, almost no consumption)

Workers' wages: 900 yuan (one furnace is operated by 3 people in shifts)

Total cost: 24000+1000+400+900=26300 yuan

2) Earnings

Tire oil: 4800 yuan / ton * 5.4 tons = 25920 yuan;

Carbon black: 800 yuan/ton*3.6 tons=2880 yuan;

Steel wire: 2000 yuan/ton*1.2 tons=2400 yuan;

Total income: 25920+2880+2400=31200 yuan

3) Profit:

Profit: total income - total cost = 31200-26300 = 4900 yuan

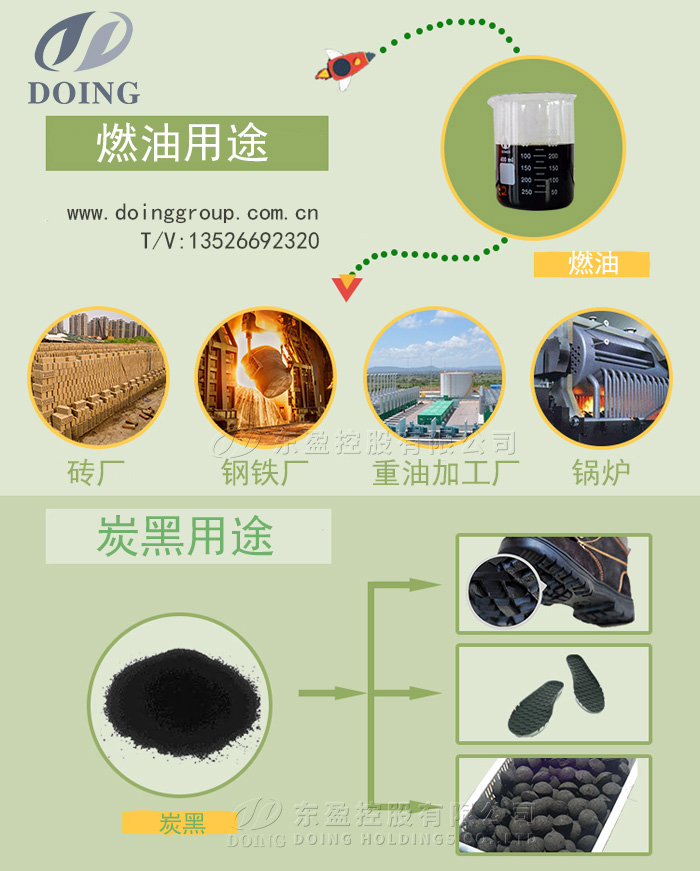

Tire refining products and their uses

Tire refining products and their uses

According to the minimum annual processing capacity requirement of 20,000 tons in the "Industry Standard Conditions for Comprehensive Utilization of Waste Tires", it is necessary to install 5 sets of waste tire refining equipment with a daily processing capacity of 12 tons. The profit is 24,500 yuan, which is 7.35 million yuan based on 300 days a year. The average market price of a set of waste tire refining equipment with a daily processing capacity of 12 tons is about 300,000 yuan, and 5 sets of equipment need about 1.5 million yuan. In addition to depreciation costs such as workshops and machines, the actual profit of waste tire refining is also very high. It can be seen from this that it is really profitable to engage in waste tire refining projects, and it will pay back quickly and earn you a lot of money. If the tens of millions of tons of waste tires produced nationwide are processed in a standardized manner, an industrial chain with an annual output value of over 10 billion yuan may be formed.

12 tons of waste tire refining equipment

12 tons of waste tire refining equipment

The premise for the state to encourage and support waste tire refining projects is to achieve environmental protection, effective recovery and recycling. Therefore, the key step to whether the waste tire refining project can be put into operation smoothly and earn huge profits is to choose environmentally friendly waste tire refining equipment. Henan Dongying's environmentally friendly waste tire refining equipment is equipped with environmental protection treatment devices for the waste smoke, waste water, waste gas and odor generated during the oil refining process, which meet environmental protection standards and can help customers successfully obtain environmental impact assessment procedures.