DOING HOLDINGS

DOING HOLDINGS

When investing in a set of sweet potato starch processing equipment, investors should not only pay attention to the price of the sweet potato starch equipment, but also consider whether the sweet potato starch market matches the production capacity demand of the sweet potato starch equipment. The output and quality of the sweet potato starch produced are in line with the sweet potato starch product market. Positioning and requirements, equipment environmental protection, pre-sales and after-sales services, etc.

Henan Jinrui Company reminds you to base your selection of sweet potato starch processing equipment on the following five aspects:

When investing in a sweet potato starch processing plant, sweet potato starch processing equipment should be selected based on the specific sweet potato starch demand. For example, the investor’s overall processing demand in the initial stage of the factory was small, and he purchased some equipment with a suitable output. However, with the substantial increase in operating capacity, he began to expand the plant and gradually upgrade the sweet potato starch processing equipment. This means that the demand for sweet potato starch processing should match the equipment production capacity, reasonably control the investment budget, and reduce risks.

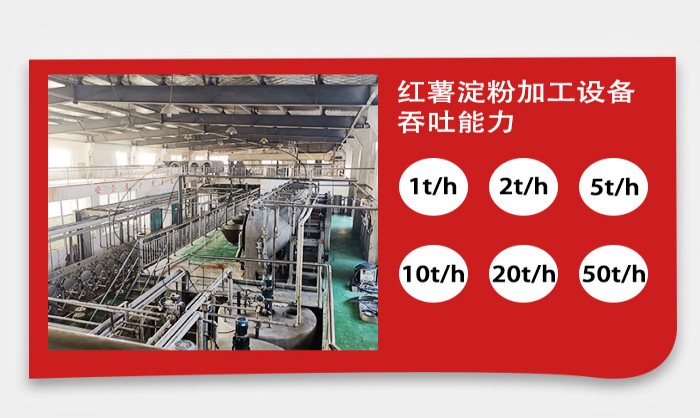

Jinrui sweet potato starch equipment processing capacity

Jinrui sweet potato starch equipment processing capacity

At present, the new automated sweet potato starch processing process is: cleaning - crushing - screening and filtering - refining - dehydration - drying. This is the standard process for producing edible sweet potato starch. It not only has high processing efficiency, but also closely cooperates with each link and operates in a streamlined manner to ensure the powder yield and purity of sweet potato starch. However, the production scale and modernization level of most sweet potato starch processing plants in my country are relatively low, and most of them still produce starch by combining machinery and labor. Therefore, to build small and medium-sized sweet potato starch processing plants in second-tier and third-tier cities, it is recommended to choose sweet potato starch processing equipment with more scientific and reasonable sweet potato starch processing technology and more modern processing technology within the acceptable range.

Sweet potato starch processing production line equipment

Sweet potato starch processing production line equipment

The quality considerations of sweet potato starch processing equipment include: manufacturing materials, electromechanical, equipment thickness, and even small parts of the equipment, which are directly related to the use experience and service life of sweet potato starch processing equipment, and will also affect the quality of sweet potato starch production. There are two main materials used for manufacturing sweet potato starch equipment: carbon steel and stainless steel. A large amount of water is used in the processing of sweet potato starch. If the equipment is soaked in water for a long time, corrosion and rust will occur when using ordinary materials, which will affect the normal operation of the equipment and the quality of the finished product.

Sweet potato starch production line

Sweet potato starch production line

In recent years, my country has vigorously advocated the implementation of environmental protection policies, strict requirements on the discharge of unqualified pollutants, and requires the vibration frequency, noise and processing waste discharge of starch processing equipment to be controlled within the standard range. Especially for the treatment of starch processing waste, potato residue and starch wastewater, there must be corresponding treatment and processing equipment to avoid environmental pollution and waste of resources.

Advantages of sweet potato starch production line

Advantages of sweet potato starch production line

Pre-sales and after-sales issues are the focus of testing the manufacturing strength and service capabilities of a sweet potato starch processing equipment manufacturer. In the early stage of purchasing sweet potato starch equipment, the sweet potato starch processing equipment manufacturing company should provide a reasonable sweet potato starch processing production line plan based on customer needs, take customers to conduct actual inspections of sweet potato starch processing equipment, and provide professional equipment installation services. In the later use process, customers may encounter problems such as equipment failure and parts damage. We will provide solutions as soon as possible to provide users with a good service experience. We will listen to user feedback, improve the equipment, and enhance excellent usability and operation. feel. Pre-sales and after-sales guarantees are the key to selecting sweet potato starch processing equipment. Henan Jinrui Company provides technical design, equipment production, installation and commissioning, technical training, technical transformation, post-maintenance and other services.

Jinrui Sales Guaranteed before and after sales

Jinrui Sales Guaranteed before and after sales

Only by choosing the right sweet potato starch processing equipment can the production of sweet potato starch achieve higher efficiency. Jinrui Food Engineering Technology Co., Ltd. has been engaged in the potato deep processing industry for more than ten years. It provides a complete set of "turnkey" engineering services and can customize sweet potato starch processing equipment according to your processing needs and actual conditions!