DOING HOLDINGS

DOING HOLDINGS

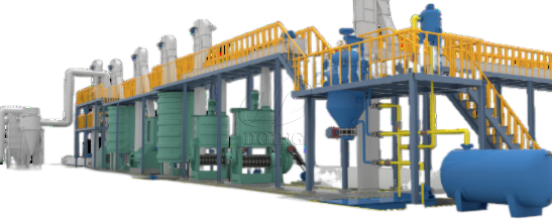

Henan Glory cooking oil processing machine adopts advanced pressing/leaching technology at home and abroad, which can be used for pressing or leaching more than 30 kinds of oil seeds, such as peanuts, soybeans, rapeseeds, sunflower seeds, cottonseeds, tea seeds, corn germ, rice bran, etc. High oil yield rate, high high degree of automation. Glory's engineers can provide one-stop solution and turn-key project of different oil seeds and processing requirements of different oils, including equipment customization, equipment installation guidance, equipment debugging, and plant design and upgrading.

Oil seeds pretreatment refers to the treatment process before the oil seeds enters the oil press or solvent extractor, including cleaning, shelling, crushing, softening, flaking, puffing, cooking. After pretreatment, the impurities in the oil seeds are removed, which can prolong the service life of equipment and improve the extraction rate of vegetable oil. Because different oil seeds has different features, the oil seeds pretreatment process and equiment will be designed according to the customer's raw material. The same goes for the choice of oil press type.

For more configuration plans, please leave a message or call for consultation

For more configuration plans, please leave a message or call for consultation