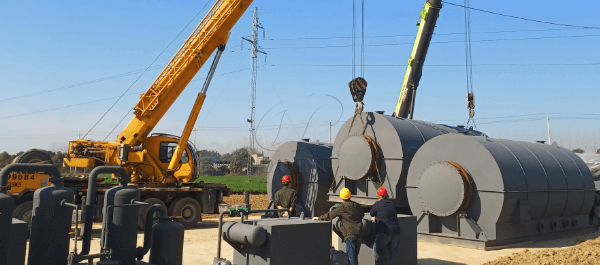

Feed

Send waste tires into the pyrolysis reactor through the feeder, close the furnace door, heat the reactor, and keep the tires in a closed environment for high-temperature pyrolysis. (feeder)

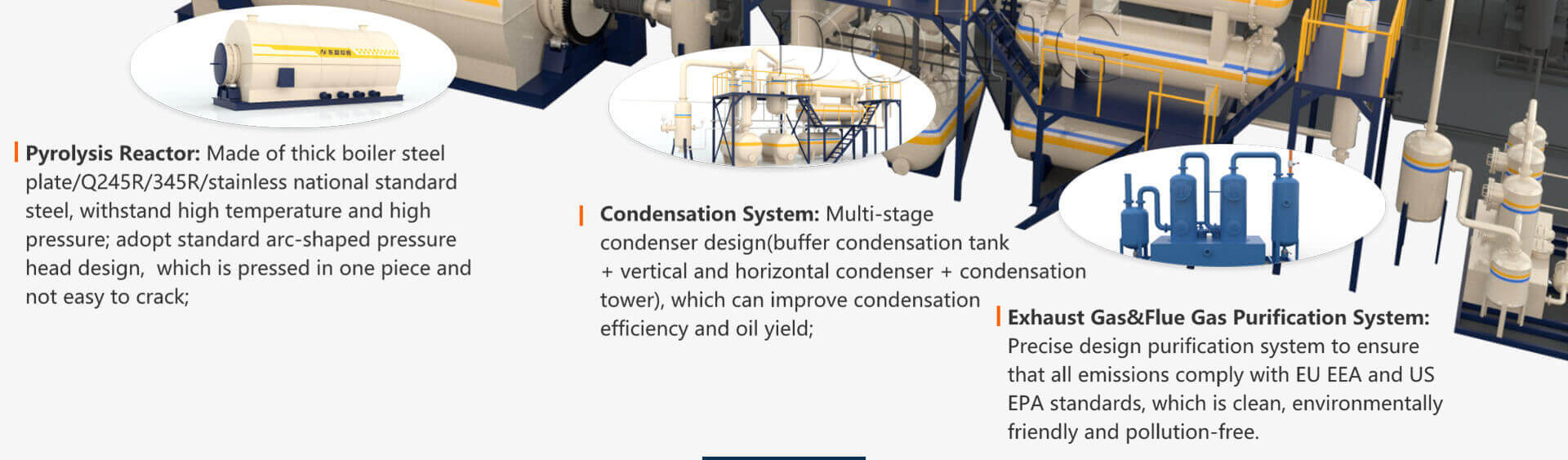

Crack

After the feeding is completed, the waste tires are pyrolyzed in the pyrolysis reactor, and the furnace is continuously heated to make the reactor reach a certain temperature, and oil gas, carbon black and gas are produced. (Pyrolysis Reactor)

Condensation

The oil and gas produced by cracking first enter the buffer tank to buffer the flow rate and settle impurities, and then enter the vertical condenser, horizontal condenser and condensation tower three-stage condensation system to fully condense into oil. (buffer tank, vertical condenser, horizontal condenser, condensation tower, water seal)

Exhaust gas purification

The remaining non-condensable gas enters the exhaust gas purification device, and returns to the pyrolysis reactor as fuel after purification, which is energy-saving and environmentally friendly. (Desulfurization and deodorization tower)

Flue gas purification

The flue gas generated during the pyrolysis process is treated by the flue gas purification system - desulfurization purification tower, and then discharged up to standard (desulfurization dust removal tower, water film dust collector, pulse dust collector)

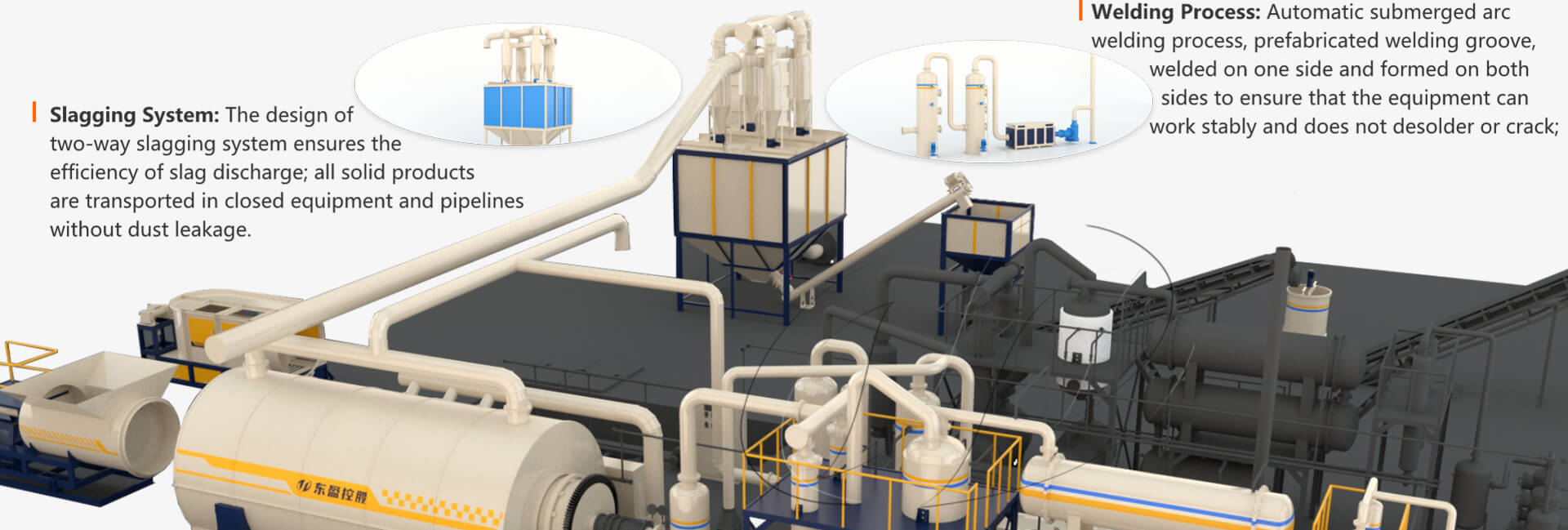

Carbon black slagging

The residual substance in the reactor—carbon black, is discharged and collected through the carbon black slag discharge system. (Carbon black air transportation system, screw elevator)

Steel wire collection

When the temperature of the reaction kettle drops to about 50°C, pull out the steel wire in the reaction kettle through a wire drawing machine. (drawing machine)