DOING HOLDINGS

DOING HOLDINGS

How many tons of waste tires can be refined into one ton of oil? Under normal circumstances, the oil yield of tire refining is about 45-52%, which means that one ton of tires can extract at least about 450 kilograms of oil. According to this conversion formula, 2.3 tons of tires can extract 1 ton of oil. Of course, the above data is for reference only, because the tire refining oil yield rate fluctuates in a small range due to the influence of many factors, such as: waste tire type, waste tire refining equipment process design, and control of refining time and temperature, etc.

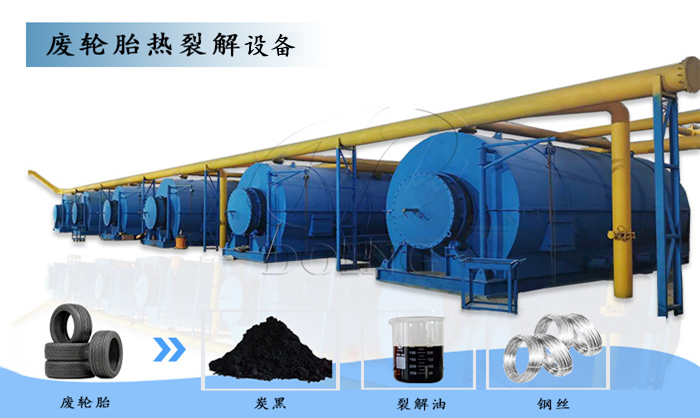

Waste tire refining equipment

Waste tire refining equipment

First of all, different types of waste tires have different rubber contents, which will directly affect the oil yield of tire refining from the source. For example, large cars, truck tires, and engineering tires have the highest oil yield rate, which is maintained at around 50%. 1 ton of waste tires can refine about 500 kilograms of oil, so 2 tons of scrap tires can refine 1 ton of oil; followed by cars , motorcycle, and bicycle tires, the oil yield is about 40%. One ton of waste tires can extract about 400 kilograms of oil, so 2.5 tons of waste tires can extract 1 ton of oil; then there are rubber cable sheaths, shoe soles, and rubber mats. The oil yield rate of rubber products such as rubber miscellaneous materials and rubber miscellaneous materials is about 30% to 35%, and it takes about 3 tons of raw materials to refine 1 ton of oil.

Oil production rates of different types of tires

Oil production rates of different types of tires

Secondly, since waste tires are cracked and refined through refining equipment, the tire refining oil yield is not only closely related to the raw materials, but also closely linked to the process design of the waste tire refining equipment, such as: whether the cracking system can convert waste The tires are fully cracked and the condensation system can fully condense 99% of the oil vapor into oil.

Waste tire refining equipment

Waste tire refining equipment

Henan Dongying Company's waste tire refining equipment is precisely through the cracking system and condensation system The careful design and double attack ensure that the waste tire refining equipment can stably pump out oil. The pyrolysis system of Dongying's waste tire refining equipment is designed with spiral blades, rotation system and transmission system inside, so that the waste tires run along the inner wall of the reactor, advance evenly under the drive of the furnace power transmission device and directly contact the heat-transmitting surface, and are immediately accepted Heat, heat exchange is fast, heating is uniform, cracking is sufficient, and 99% cracking of oil sludge can be achieved. The condensation system adopts a multi-stage condenser design, with a combination of buffer tank + vertical, horizontal condenser + condensation tower, condensing layer by layer, with a total cooling area of 90 square meters, ensuring that 99% of oil and gas are fully cooled, and the tire refining oil yield rate is A substantial increase!

Dongying Tire Refining Equipment Condensing System

Dongying Tire Refining Equipment Condensing System

Next, the actual oil yield of tire refining depends on whether the entire refining process is standardized and whether the burner's control of the time and temperature of the waste tire refining is just right. If the refining temperature is too low, the waste tires cannot be fully cracked, and less oil and gas will be produced, which directly affects the tire's cracking rate and oil yield rate; but if the temperature is too high, the oil and gas produced will increase sharply in a short period of time. As a result, the condensing system cannot fully condense it, and the oil refining rate of tires will also become low. The same is true for oil refining time. If the oil refining time is insufficient, the oil and gas in the furnace will not be refined. Therefore, when operating waste tire refining equipment, we must grasp the refining time and temperature.

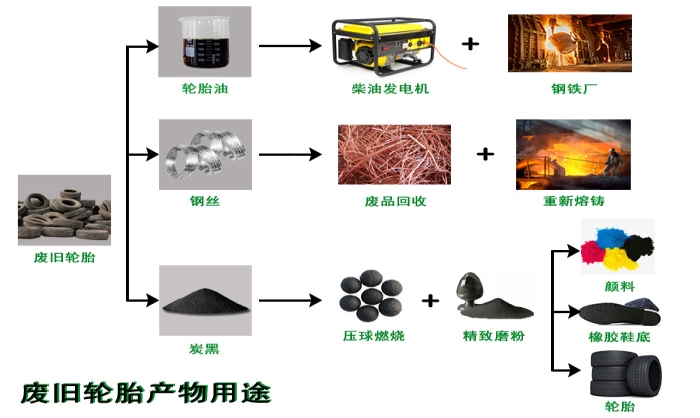

Waste tires can not only extract fuel oil, but also extract 15% steel wire, 35% carbon black and 8% combustible gas. The steel wire can be cut and removed from the tire in advance, and the price will be higher. It can also be removed from the refinery furnace by a wire drawing machine or manually after the refining. Carbon black can be packaged and sold directly, or purchased from Henan Dongying’s carbon black briquetting machine for processing and sold at a better price. The combustible gas directly enters the combustion chamber of the refinery furnace through the pipeline, and is used as fuel, which saves money and is environmentally friendly. Therefore, the entire waste tire refining process can be said to be an all-round consideration and recycling of renewable resources. Every part of the waste tires after cracking has obtained corresponding value.

Use of waste tire refining products

Use of waste tire refining products

Refining waste tires into oil is a technical job. If you want to know more about this process, please leave a message below and we will patiently answer any questions you have.