DOING HOLDINGS

DOING HOLDINGS

The environmental protection permission to shred waste wires depends on whether the dry-type waste wire shredder is used. The dry-type waste wire shredder meets the national environmental protection standards and is allowed to produce. The dry-type waste wire shredder adopts a dry physical separation process. Unlike the water-type waste wire shredder, there will be sewage discharge and waste water pollution. The Environmental Protection Bureau will also strictly investigate and dispose of it. You may be curious, why is the production of dry waste wire crusher allowed to comply with environmental standards?

Dongying dry waste wire crusher

Dongying dry waste wire crusher

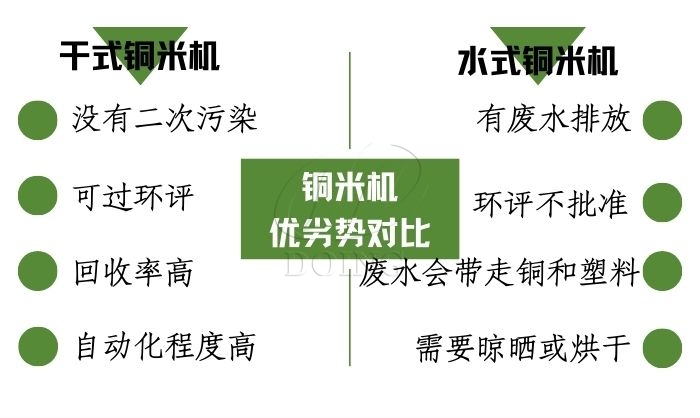

This starts with the production process of the dry-type waste wire shredder. The dry-type waste wire shredder adopts a dry physical separation process. The conventional production process includes: shredding, crushing, sorting and dust removal. Shredders and crushers are mainly used to preprocess waste cables and wires into copper-plastic mixed particles, and then the air flow specific gravity separator uses the different specific gravity of copper and plastic to sort. Since some waste cables and wires are generally dirty, with a lot of dust or oil on them, Henan Dongying dry waste wire crusher will also be equipped with cyclone dust removal and pulse dust removal equipment to reduce dust pollution and meet national environmental protection standards, so it is environmentally friendly It is allowed to use dry waste wire crusher for production.

Comparison of the advantages and disadvantages of dry and water-type waste wire crushers

Comparison of the advantages and disadvantages of dry and water-type waste wire crushers

The water-type waste wire crusher is different. The water-type waste wire crusher uses a gravity shaking table to sort. During the production process, water is continuously added to use buoyancy to screen out copper and plastic. However, when discharging waste water, Dust and oil on the skin, as well as toxic substances such as plasticizers, will also be emitted together. In addition to causing water waste and water pollution, this production method also produces wet copper and plastic, which requires manual drying or the installation of a dryer. This not only increases labor and material costs, but also affects the quality of the copper. , the price on the market is slightly lower.

At present, the water-type waste wire crusher cannot pass the environmental protection review, and there is no guarantee that it can continue to be produced in the future. Whether it is from the perspective of environmental protection or the sustainable development of crushed waste wires, it is recommended that everyone use a dry waste wire crusher. The waste wire crusher produced by Henan Dongying complies with environmental standards and does not require additional copper drying Or add a dryer, and the sorting rate can reach more than 99%. At the same time, Henan Dongying will also provide customers with professional information to help customers handle environmental impact assessment procedures. If you have any questions about environmental protection, you are welcome to consult Henan Dongying.