DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Chongqing 50t/d continuous waste tire refining equipment officially put into operation

Home>Global Cases>Chongqing 50t/d continuous waste tire refining equipment officially put into operation

Win customer reputation with high-quality service! After the 50 tons/day continuous waste tire refining equipment sent from Henan Dongying High-tech Industrial Park arrived at the customer site in Chongqing, under the guidance of Dongying after-sales engineers, the installation and commissioning work was completed on December 5, 2021. The entire waste tire refining The production line equipment is running smoothly and will be officially put into production soon. As the second cooperation between Henan Dongying and Chongqing customers, this continuous waste tire refining production line equipment will play a positive role in creating new profit growth points for customers and realizing automated and intelligent production.

The following is the installation site of Chongqing waste tire refining project:

Installation site of Chongqing 50t/d continuous tire refining equipment

Installation site of Chongqing 50t/d continuous tire refining equipment

Installation site of Chongqing 50t/d continuous tire refining equipment

Installation site of Chongqing 50t/d continuous tire refining equipment

Installation site of Chongqing 50t/d continuous tire refining equipment

Installation site of Chongqing 50t/d continuous tire refining equipment

The customer in Chongqing started cooperation with Henan Dongying as early as 2017, when he purchased a 12t/day intermittent waste tire refining equipment. After four years, the equipment is still running well and has brought him considerable benefits. Economy Profit. During these four years, Dongying staff regularly followed up and returned to customers, continued to pay attention to the production situation of the tire refinery, and answered the problems encountered by customers in actual production in a timely manner. The multi-faceted technical support is highly praised.

Dongying technical team

Dongying technical team

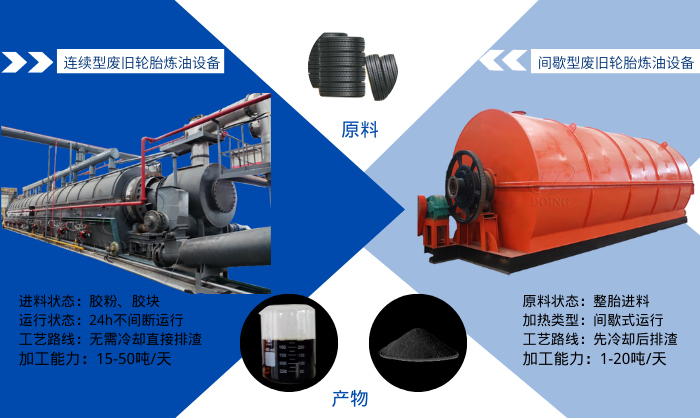

With the country's strong support for the comprehensive utilization of waste tires and the continuous inclination of related policies, it is a shot in the arm for the waste tire refining industry. The customer in Chongqing is also very optimistic about the waste tire refining industry, and under the influence of this good news, he resolutely decided to expand the production scale, and immediately contacted our project manager to inform him of the specific demands. When the customer learned about Dongying's new continuous waste tire refining equipment, he expressed his desire to enter the plant to learn more about the differences and detailed designs of the two equipments. After the customer went into the factory again to inspect the equipment, he felt that the continuous waste tire refining equipment was more in line with his current needs in terms of equipment configuration, safety and environmental protection, or continuous production. According to the processing capacity and scale of the customer's refinery, our engineers provided a 50 tons/day continuous waste tire refining equipment processing plan.

Continuous vs intermittent waste tire refining equipment

Continuous vs intermittent waste tire refining equipment

After nearly two months of overtime production, the Chongqing customer's 50 tons/day continuous waste tire refining equipment has finally completed the production and manufacturing tasks as scheduled. The equipment and all its accessories have been fully assembled with 12 large trucks. It will start on June 4, 2021. Batches are sent to the site of the waste tire refining project of Chongqing customers.

Chongqing continuous waste tire refining equipment delivery site

Chongqing continuous waste tire refining equipment delivery site

Due to the huge size of the equipment and the complexity of the installation process, Dongying immediately dispatched an engineer team and an installation team to the Chongqing customer's waste tire refining project site after the customer received the goods, and participated in the installation, commissioning and trial operation of the equipment throughout the process, and solved the installation at any time problems encountered in order to ensure its rapid and smooth commissioning and operation. At the same time, our engineers also conduct systematic technical training for the operators of the customer's factory to ensure the standardized operation of the continuous waste tire refining equipment and avoid equipment failure due to improper operation.

Chongqing continuous waste tire refining equipment installation

Chongqing continuous waste tire refining equipment installation

In the production quality link of Henan Dongying continuous waste tire refining equipment, the quality of each component of the machine is strictly controlled to ensure that the quality of the equipment is controllable at the processing end, assembly end, debugging end, and supervision end. , to ensure stable performance and reliable operation of the equipment. For more information about the follow-up progress of the continuous waste tire refining project in Chongqing, please continue to pay attention to Henan Dongying!