DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>The waste tire pyrolysis project with an annual processing capacity of 20,000 tons in Tianmen, Hubei was officially put into operation

Home>Global Cases>The waste tire pyrolysis project with an annual processing capacity of 20,000 tons in Tianmen, Hubei was officially put into operation

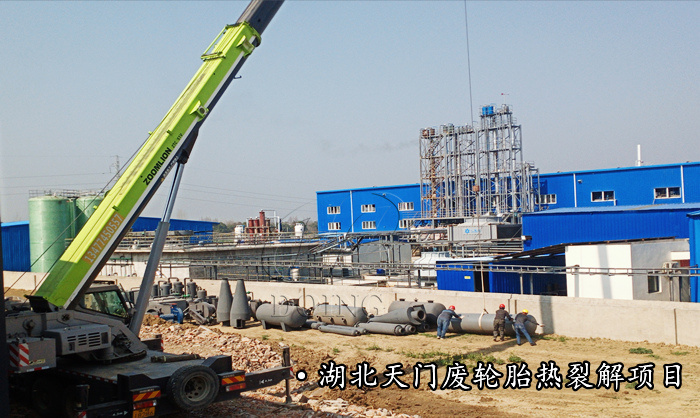

On December 29, 2021, a solid waste resource utilization project with an annual processing capacity of 2,000 tons in Tianmen, Hubei - the waste tire pyrolysis project entered the final stage of installation and perfection, and it can be delivered to customers after commissioning is completed. Landed and put into production. Henan Dongying Company participated in the construction of this project. From project planning, equipment selection, construction, and installation, Dongying Company provides full-service services, focusing on high-standard and sustainable construction requirements, and creates an intelligent benchmark solid waste project for customers. Resource comprehensive utilization project.

Hubei Tianmen waste tire pyrolysis project installation site

Hubei Tianmen waste tire pyrolysis project installation site

Installation site

Since 2020, Hubei Province has taken the "zero-waste city" pilot project as a concrete action to thoroughly implement Xi Jinping's ecological civilization thought, focusing on continuously promoting the reduction of solid waste at the source and the construction of resource utilization capacity, minimizing the amount of landfill, and will The environmental impact of solid waste is minimized. As a large-scale local environmental protection enterprise, the client company joined hands with Henan Dongying to jointly build a waste tire pyrolysis project and jointly contribute to the construction of a "waste-free city".

Hubei Tianmen waste tire pyrolysis project site

Hubei Tianmen waste tire pyrolysis project site

Dongying workers are installing equipment

Dongying workers are installing equipment

Dongying workers installation site picture

Dongying workers installation site picture

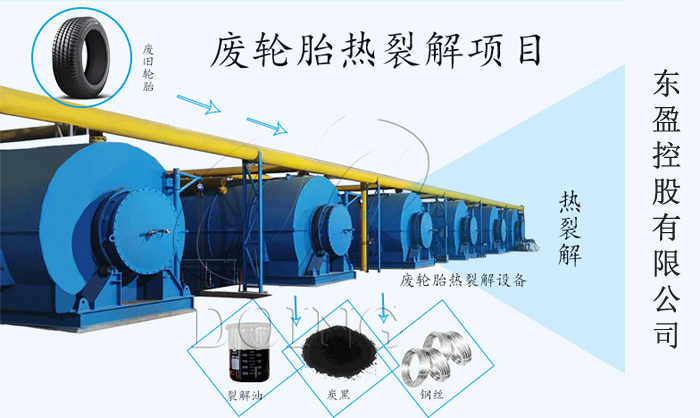

Project Outlook

The raw material of this project is mainly waste tire treatment, and 6 sets of 12 tons/day waste tire pyrolysis equipment are designed, with an annual processing capacity of 2,000 tons. This set of waste tire pyrolysis production line is fully equipped by Henan Dongying Company. It adopts the process plan of multi-stage reactor parallel treatment, and is equipped with a proprietary combined flue gas tail gas purification treatment equipment. The "three wastes" of waste are purified and treated, and the cleanliness and environmental protection meet the standards. After waste tires are pyrolyzed at high temperature, high value-added energy products such as pyrolysis oil, carbon black, and steel wire can be produced to realize the recycling and reuse of waste resources.

Waste tire pyrolysis equipment and its products

Waste tire pyrolysis equipment and its products

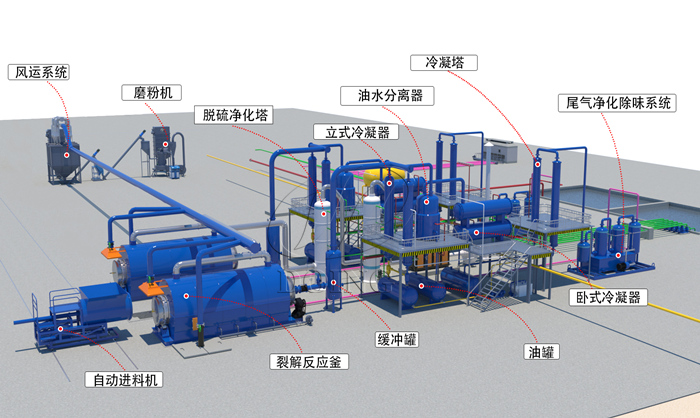

Core equipment - waste tire pyrolysis equipment

This set of core equipment is mainly composed of automatic feeder, pyrolysis reactor, water seal, multi-stage condensation system, carbon black air transportation system, deodorization system, desulfurization and dust removal system, negative pressure system and PLC control cabinet and other equipment components to realize Automated, intelligent and integrated control production.

Pyrolysis equipment for waste tires

Pyrolysis equipment for waste tires

Henan Dongying Huanzi Technology Co., Ltd. relies on the advantages of the whole industry chain integrating technology research and development, equipment manufacturing, and operation management. , design, construction, construction of the whole process of service guidance and implementation.