DOING HOLDINGS

DOING HOLDINGS

Tapioca starch, also called cassava starch, has a wide range of application in industry. Do you want to extract tapioca starch from cassava? Henan Jinrui, the professional tapioca starch extraction equipment manufacturer, will tell you how to extract tapioca starch from cassava by advanced tapioca starch extraction process.

To extract tapioca starch from cassava requires six series of processes such as cleaning, crushing, filtering, purification, dewatering and drying. Henan Jinrui will introduce it for you step by step.

The first process of tapioca starch extraction is cleaning, which is to remove sand, mud and other impurities from cassava raw material. And the dry sieve, paddle washing machine will be used in the cleaning process of tapioca starch extraction.

Cassava starch cleaning machine

Cassava starch cleaning machine

Dry sieve can remove dirt attached to the surface of cassava by rotational friction. In addition, the paddle washing machine designed by Henan Jinrui company adopts the principle of countercurrent washing to clean the cassava and remove the first layer of skin on the surface of the cassava at the same time.

The next process of tapioca starch extraction is to crush the cassava cleaned. And in crushing process, we need to use the cutting machine and rasper in order to extract more starch from the cassava.

Cassava crushing machine

Cassava crushing machine

Cutting machine cuts the cassava into small pieces to facilitate the subsequent grinding of the cassava by the rasper. And the rasper provided by Henan Jinrui can achieve 96% crushing rate. The rasper can release more bound starch by bidirectional rasper, which is one of the important factors that can affect the final extraction rate of tapioca starch.

The crushed cassava pulp needs to go through a filtration process to remove fiber impurities in the cassava pulp. In order to extract high-quality tapioca starch, a centrifuge sieve and a fine fiber sieve are required in the filtering process.

Cassava starch filtering machine

Cassava starch filtering machine

The centrifuge sieve and fine fiber sieve separate the fibers from the cassava pulp under the action of centrifugal force and gravity. If you ultimately want to achieve a high tapioca starch extraction rate, the centrifuge sieve designed by Henan Jinrui is a good choice for you, which adopts multi-stage sieving to reduce the starch loss rate during tapioca starch extraction.

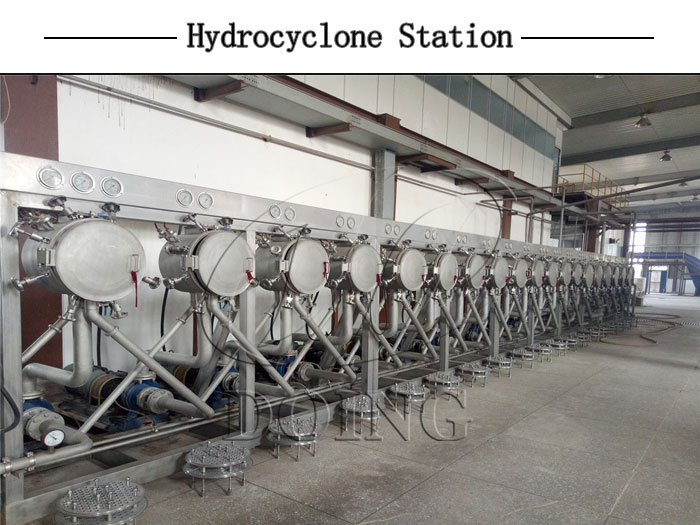

In addition to fiber impurities, tapioca starch also contains cell fluid and protein. Therefore, we also need to carry out a purification process in order to extract high-quality tapioca starch. And the hydrocyclone station will be used in the purification process.

Cassava starch purification equipment

Cassava starch purification equipment

Henan Jinrui’s hydrocyclone station integrates the functions of recovery, concentration and refining. In addition, it adopts an 18-stage series design, which can greatly reduce the loss rate during the extraction of tapioca starch.

Recommend Reading: A guide for setting up a cassava starch processing factory

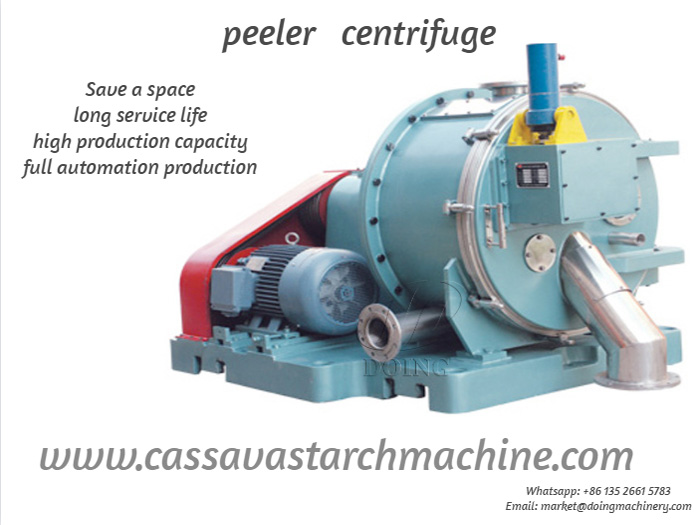

High-quality tapioca starch also has high requirements for the water content. Therefore, the Extracting tapioca starch needs to go through a dewatering process. In this process, a peeler centrifuge will be used. The water content of tapioca starch processed by this machine can reach 36.5%-38%.

Cassava starch dewatering machine

Cassava starch dewatering machine

Drying is the last process of tapioca starch extraction, we need to use the flash dryer for tapioca starch drying.

The flash dryer designed by Henan Jinrui adopts negative pressure that effectively reduces the loss of tapioca starch. In addition, the pipeline uses a pulse tube design, that increases the residence time of tapioca starch and can achieve the optimal drying effect.

Cassava starch drying machine

Cassava starch drying machine

The quality of the dried tapioca starch is relatively high, but in order to facilitate storage or sale, we often use sifter sieve and packaging machine to package the final extracted tapioca starch.

The above are the complete processes about how to extract tapioca starch from cassava. Henan Jinrui can offer complete tapioca starch extracting equipment. If you want to learn more about the tapioca starch extraction, welcome to consult us!