DOING HOLDINGS

DOING HOLDINGS

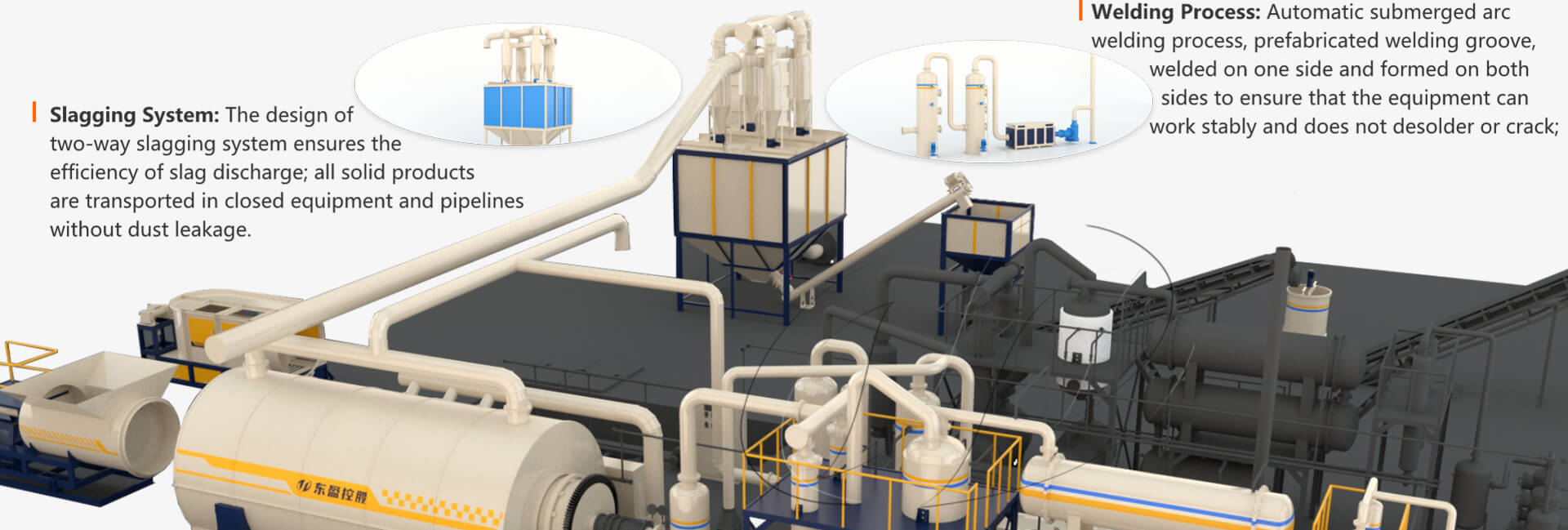

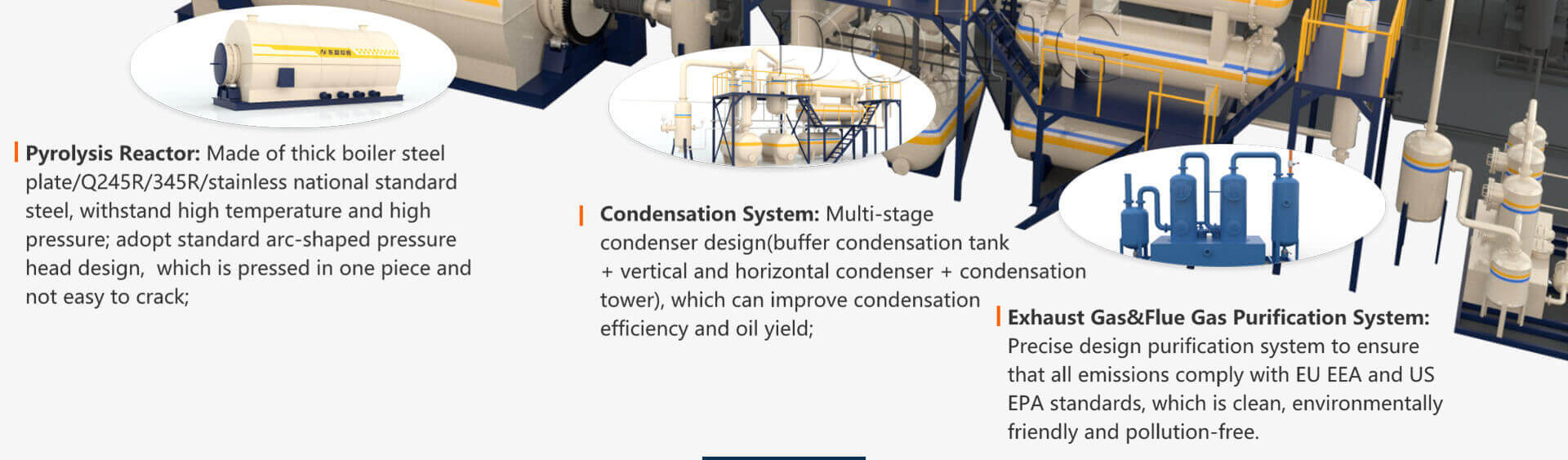

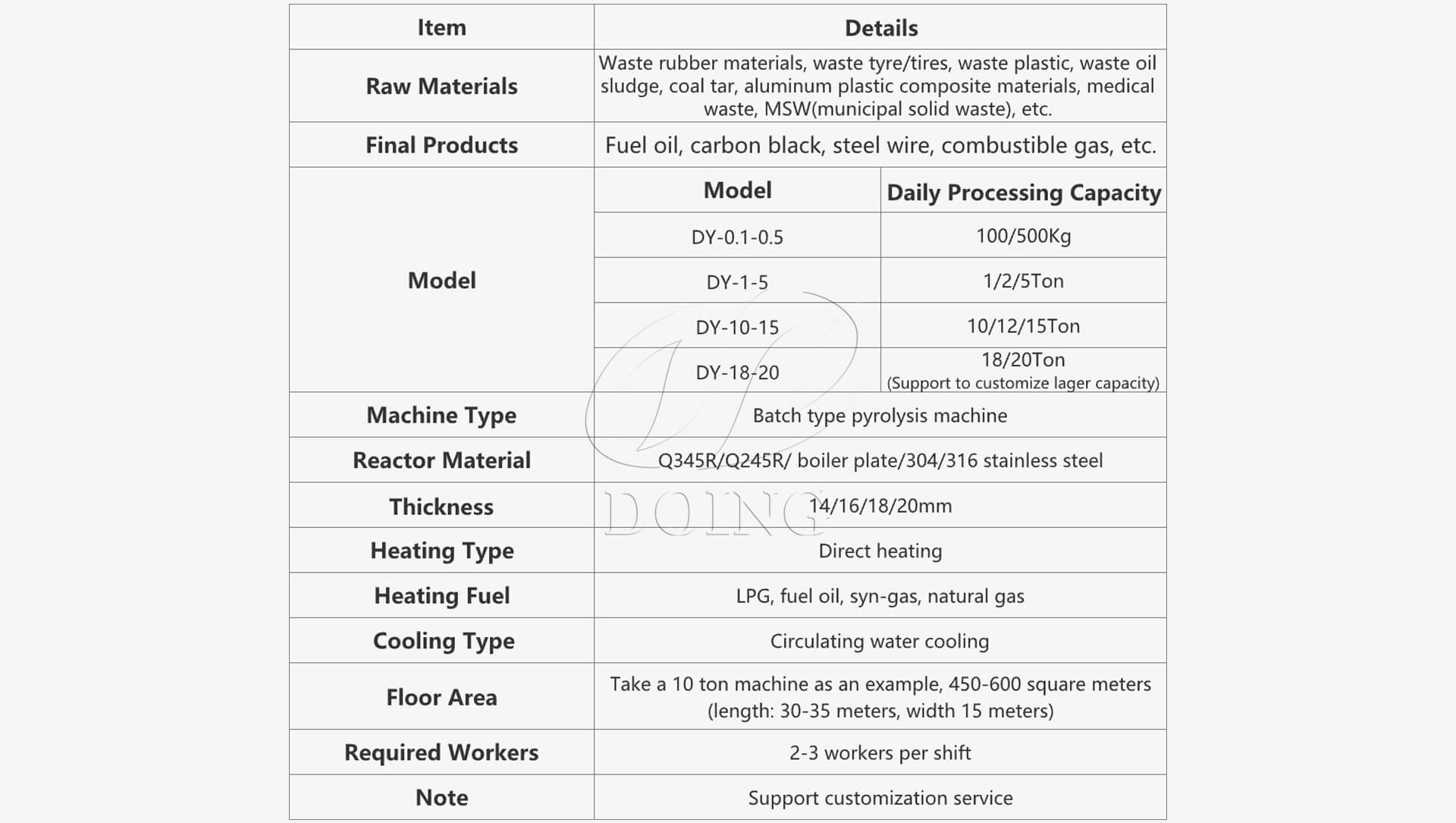

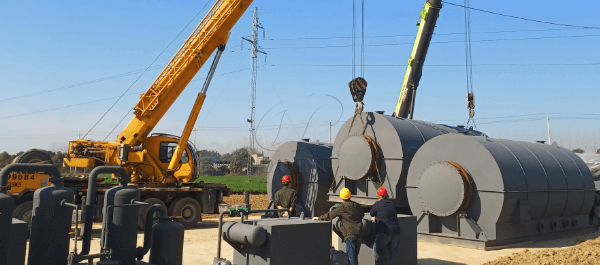

DOING batch pyrolysis plant uses low-temperature pyrolysis technology to fully crack the polymers in organic waste such as waste tires/rubber/plastics/aluminum plastics/oil sludge and restore them to small molecules or monomer states. Eventually, we can get high value-added products such as fuel, carbon black, and steel wire. There are multiple scales of batch pyrolysis plants for sale, which meet the emission standard and have the advantages of stable&safe operation, long service life, etc.