DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>DY-C-50 fully automatic tire pyrolysis plant put into operation in Russia

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>DY-C-50 fully automatic tire pyrolysis plant put into operation in Russia

In order to achieve sustainable development and reduce operating costs, many companies have begun to turn to the reuse of waste resources and the production of alternative fuel oil. Henan DOING Company was fortunate to participate in and successfully complete the production and installation of a DY-C-50 fully automatic tire pyrolysis plant for a Russian customer in April 2023.

Here is the project picture of fully automatic tire pyrolysis plant installed in Russia:

Fully automatic pyrolysis machine instain Russia project picture

Fully automatic pyrolysis machine instain Russia project picture

The Russian customer owns a factory that requires a large amount of fuel every day to meet processing needs. However, local oil prices fluctuate greatly and operating costs are high. In order to find a more stable and economical way to supply fuel, the customer decided to invest in a waste tire pyrolysis project to produce alternative fuel oil for self-use.

Russian customers paid great importance to the technical process of the pyrolysis plant, the strength of the supplier, and whether there are mature project cases for reference. We Henan DOING Company was their first choice, and we recommended our fully automatic tire pyrolysis plant to Russian customer factories, considering their large daily demand for fuel oil, high technical requirements for stable and efficient operation, and sufficient funds.

DOING fully automatic tire pyrolysis plant advantages

DOING fully automatic tire pyrolysis plant advantages

DY-C-50 fully automatic tire pyrolysis plant has the following characteristics. First, the fully automatic tire pyrolysis plant has the characteristics of large daily processing capacity and high processing efficiency. The Russian fully automatic waste tire pyrolysis project uses excellent technology to efficiently convert 50 tons of waste tires into high-quality alternative fuel oil, with an oil yield of up to 40-45%.

Fully automatic tire pyrolysis plant exported to Russia

Fully automatic tire pyrolysis plant exported to Russia

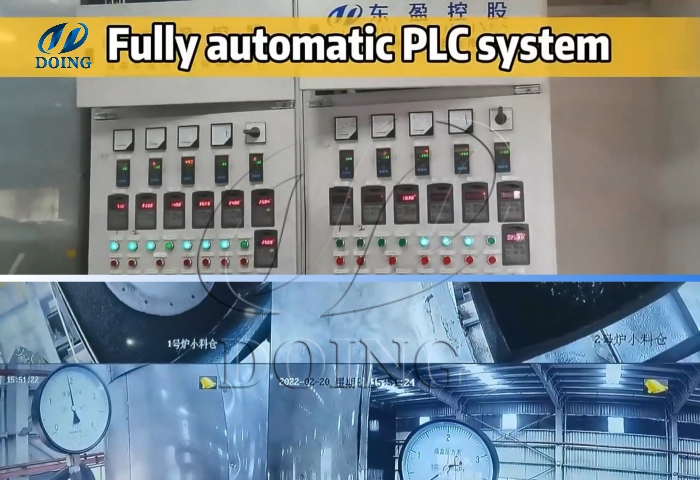

Secondly, DOING fully automatic tire pyrolysis plant adopts a PLC automatic control system to achieve automatic control of the entire production line, which not only improves production efficiency, but also reduces manual operation, and can monitor and adjust the working status of each link in real time to ensure the stability and reliability of pyrolysis production. The design of automatic feeding and discharging makes the entire production process smoother, reduces the opportunity for manual intervention, and reduces labor input costs.

PLC control systen of fully automatic tire pyrolysis plant

PLC control systen of fully automatic tire pyrolysis plant

In addition, the Russian automatic tire pyrolysis project also has the advantages of energy saving and labor saving. The fully automatic tire pyrolysis plant adopts excellent flue gas preheating circulation technology to reuse the syn-gas produced in pyrolysis process, reduce energy consumption, and reduce negative impacts on the environment. This not only helps companies reduce operating costs, but also meets environmental protection requirements.

As a global professional manufacturer and supplier of solid waste pyrolysis plant and waste oil to diesel distillation equipment, Henan Doing Company played a key role in the Russian fully automatic tire pyrolysis project. If you also want to produce alternative fuels, please contact us to be responsible for the design, manufacture, installation and commissioning of the project for you.