DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>4 sets of 15TPD oil sludge recovery pyrolysis plants project in Colombia

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>4 sets of 15TPD oil sludge recovery pyrolysis plants project in Colombia

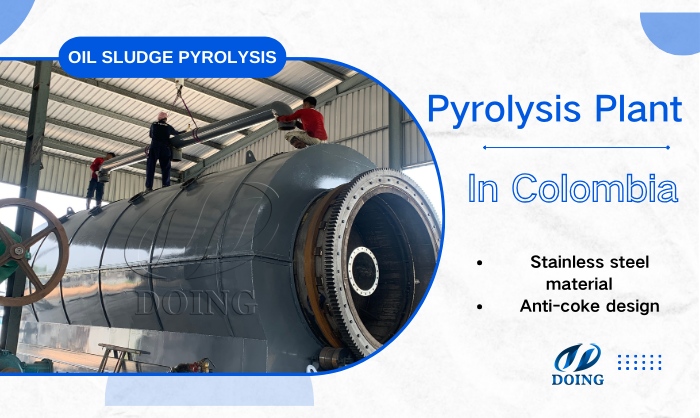

On October 23, 2023, four sets of 15TPD oil sludge recovery pyrolysis plants from Henan Doing Company were successfully installed in Colombia and passed the acceptance inspection. The oil sludge recovery pyrolysis plants are all custom-made from 304 stainless steel and equipped with special design to better solve the coking and wall sticking phenomenon that customers are worried about.

DOING oil sludge recovery pyrolysis plant project in Colombia

DOING oil sludge recovery pyrolysis plant project in Colombia

Oil sludge recovery pyrolysis plant solution

The Colombian customer is engaged in the waste oil recycling industry and has its own stable waste oil sludge supply. This cooperation with Henan Doing aimed to find new technologies to solve the coking and wall sticking phenomenon of pyrolysis plant. We all know that during the pyrolysis process of waste oil sludge, therefore, pyrolysis plant requires workers to clean it regularly to avoid affecting the heating effect and production efficiency of the pyrolysis reactor, which is time-consuming and labor-intensive.

DOING oil sludge recovery pyrolysis plant with anti-coke design

DOING oil sludge recovery pyrolysis plant with anti-coke design

In May 2023, our Colombian customers visited us and our factory. Our sales manager and engineer explained and demonstrated our new decoking process in detail. As the main furnace of the oil sludge recovery pyrolysis plant rotates, the decoker prevents coking and removes coke. In addition, it is recommended that customers choose 304 stainless steel for the inner liner of the main pyrolysis plant reactor, which has better acid and corrosion resistance and long service life of the equipment. The oil sludge pyrolysis technology solution provided by Henan Doing Company was highly matched with the needs of Colombian customers. Finally, four sets of 15TPD stainless steel oil sludge recovery pyrolysis plants were ordered, treating and recycling about 60 tons of oil sludge per day.

Pyrolysis plant delivery and installation

In order to assist Colombian customers in the delivery and installation of oil sludge recovery pyrolysis plants, DOING Company carried out the equipment shipments in batches. The first two sets of pyrolysis plants were loaded and shipped at the end of July 2023. They were shipped to Qingdao Port in Shandong Province and then transferred to Colombia. The latter two sets of pyrolysis equipment followed closely and were shipped a month later.

After the customer received the goods, we arranged for our engineer team to go to the customer's site to assist with installation and operation training. At the end of October 2023, we received feedback videos and positive comments from customers about the smooth installation of 60tpd oil sludge recovery pyrolysis plants project. This also marks the completion of another solid waste and hazardous waste treatment and recycling project with the assistance of Henan Doing Company.