DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>8 sets of Coal tar oil residue pyrolysis machines project installed in China!

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>8 sets of Coal tar oil residue pyrolysis machines project installed in China!

In June, 2023, 8 sets of coal tar oil residue pyrolysis machines researched and manufactured by DOING were successfully installed in China, which marks the further expansion of customer scopes and brand influence of DOING.

The customer had previously purchased coal tar oil residue pyrolysis machines from other manufacturers, but the operation was not ideal. During the oil sludge pyrolysis process, coking and wall sticking were serious, and the equipment frequently experienced malfunctions. However, the customer considered that the profits from the coal tar oil residue pyrolysis project were very considerable, and he had a steady stream of oil sludge and oil residue raw materials that needed to be recovered urgently, so he chose to change to another manufacturer to purchase equipment again.

DOING coal tar oil residue pyrolysis machine for sale

DOING coal tar oil residue pyrolysis machine for sale

After understanding the customer's actual needs and concerns, we invited the customer to visit our factory and introduced the details of our equipment and some project case operation live videos to the customer in detail. Finally, we reached friendly cooperation with our Chinese customer on 8 sets of coal tar oil residue pyrolysis machines.

The following are several keypoints of this coal tar oil residue pyrolysis machine project:

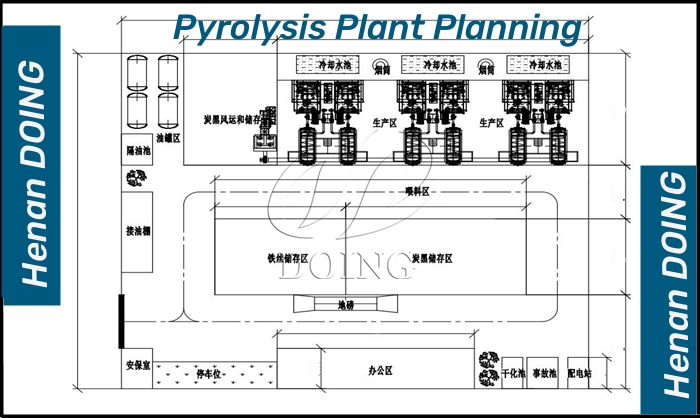

Project design is the first and most important step in the pyrolysis plant installation process. Our professional engineer team will design drawings and issue oil sludge prolysis plant customized solutions for customers based on their requirements, site conditions, tonnage of raw materials, local environmental protection requirements, etc. to satisfy customers and ensure smooth operation.

Project design provided by DOING

Project design provided by DOING

During the coal tar oil residue pyrolysis machines construction and installation stage, relevant safety regulations and operating specifications must be followed to ensure the safety, quality, and progress of the coal tar oil residue pyrolysis machines installation process. Henan DOING participated in the entire process of guiding the construction, commissioning and trial operation of these 8 sets of coal tar oil residue pyrolysis machines.

Installation site of DOING coal tar residue pyrolysis machine

Installation site of DOING coal tar residue pyrolysis machine

Supervision and inspection is an indispensable part of the coal tar oil residue pyrolysis machines installation process and can better maintain the safety and quality of the project operation process. Henan DOING Company will always observe the supervision and evaluation results of the regulatory authorities on the coal tar oil residue pyrolysis machine project.

After the coal tar oil residue pyrolysis machines are installed, standardized operations and daily maintenance and upkeep work need to be done to effectively extend the service life of the coal tar oil residue pyrolysis machines. Henan DOING Company will provide technical training for workers of the coal tar oil residue pyrolysis machine project, including standardized equipment operation, daily maintenance, safety precautions and emergency plan handling.

Operation site of DOING coal tar residue pyrolysis machine

Operation site of DOING coal tar residue pyrolysis machine

Over the past 13 years, DOING has cooperated with thousands of customers on our pyrolysis machines in various regions, such as Indonesia, Thailand, Zambia, South Africa, Brazil, Pakistan, India, Malaysia, Colombia. So if you want to get more information about our pyrolysis machine or project cases, please feel free to contact us!