DOING HOLDINGS

DOING HOLDINGS

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>Semi-continuous waste plastic pyrolysis equipment installed in Vietnam

Home>Global Cases>Waste Pyrolysis Distillation Plant Project Cases>Semi-continuous waste plastic pyrolysis equipment installed in Vietnam

Henan Doing's Vietnamese customer's 15 tons per day semi-continuous plastic pyrolysis equipment was successfully installed in September, 2024. It has now been officially put into use. The customer was very satisfied with the equipment operation state and sent us a feedback video of the waste plastic pyrolysis equipment in operation as follows.

From initial customer consultation to finalizing the installation, the entire plastic to oil pyrolysis project building process only took seven months, which shows that the Vietnamese customer trusts our company's quality and efficiency. We all departments worked together and provided customers with one-stop high quality service from plastic pyrolysis equipment solution design, production and after sales.

What Vietnamese customers decided to invest in the plastic to oil pyrolysis business, they were most concerned about are the supplier's scale and equipment's quality. Henan Doing has its own factory covering 40,000 hectares and an independent technical research and development team and has obtained various utility model patents and invention patents, which attracted our Vietnamese to send us an inquiry.

DOING factory and quality ceretificate

DOING factory and quality ceretificate

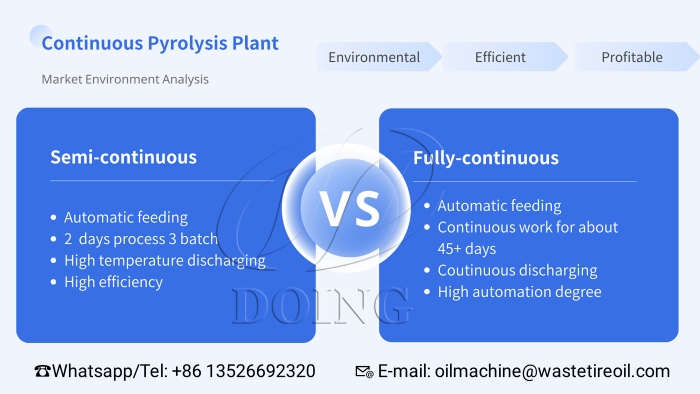

DOING sales manager learned from the inquiry and negotiation that the customer wants to recycle 15 tons of plastic particles into fuel oil per day. DOING semi-continuous type pyrolysis equipment and full-continuous type pyrolysis equipment are suitable for handling plastic particles effectively. In comparison, the fully continuous pyrolysis equipment can continuous work for about 45 days without stopping, possessing the higher efficiency. And the semi-continuous pyrolysis equipment has lower machine cost and can process 3 batches of plastic particles in two days. Our Vietnamese customer preferred the scheme of 15ton semi-continuous waste plastic pyrolysis equipment.

Comparison between semi-continuous and fully continuous pyrolysis equipment

Comparison between semi-continuous and fully continuous pyrolysis equipment

After paying a visit to DOING Company and our pyrolysis equipment manufacturing factory, and evaluating the comprehensive strengths and technology details, both parties signed the contract smoothly. And there is no doubt that our factory also fabricated and delivered plastic pyrolysis equipment timely.

Then, DOING sales manager and engineers communicated with Vietnamese customers about the construction of the factory to make full use of the plant. We arranged engineers to Vietnamese customer waste plastic pyrolysis equipment project site to guide the installation and commissioning of the waste plastic to oil equipment and teach the workers how to operate the equipment, which ensure that the waste plastic to oil equipment can run successfully under the independent operation of the workers. In September, 2024, the waste plastic to oil equipment was seamlessly transitioned into oil production.

Semi-continuous waste plastic pyrolysis equipment installed in Vietnam

Semi-continuous waste plastic pyrolysis equipment installed in Vietnam

The 15ton semi-continuous plastic pyrolysis equipment installed in Vietnam can not only bring environmental benefits, but also produce significant economic benefits. Here is the profit estimation:

| Semi-continuous Waste Plastic Pyrolysis Equipment Profit Analysis | |

| Running cost / Day | |

| Waste plastic | 15T * 40$ /T = $600 |

| Heating fuel (Just choose one from the options) | 1)Coal: 0.6T * 110$/T = $66 2)Fuel oil: 0.6T * 500$/T = $300 3)Diesel: 0.45T * 740$/T = $333 4)Gas: 225m3 * 0.35$/m3 = $78.75 |

| Power consumption | 20Kw/h=$30 |

| Water consumption | Water is for circulating use, no consumption |

| Required workers | 2 workers*$25=50$ |

| Income / Day | |

| Fuel oil | 6T * $490/T = $2940 |

| Carbon black | 1)Sell directly: 4.5T * $60/T = $270 2)Grinding: 4.5T* $185/T = $832.5 |

| Daily profit | $2584/Day |

If you require similar pyrolysis equipment, along with comprehensive technical support to guarantee the sustained and stable operation of your waste plastic pyrolysis equipment, Henan Doing Group is your reliable partner. Welcome to contact us.