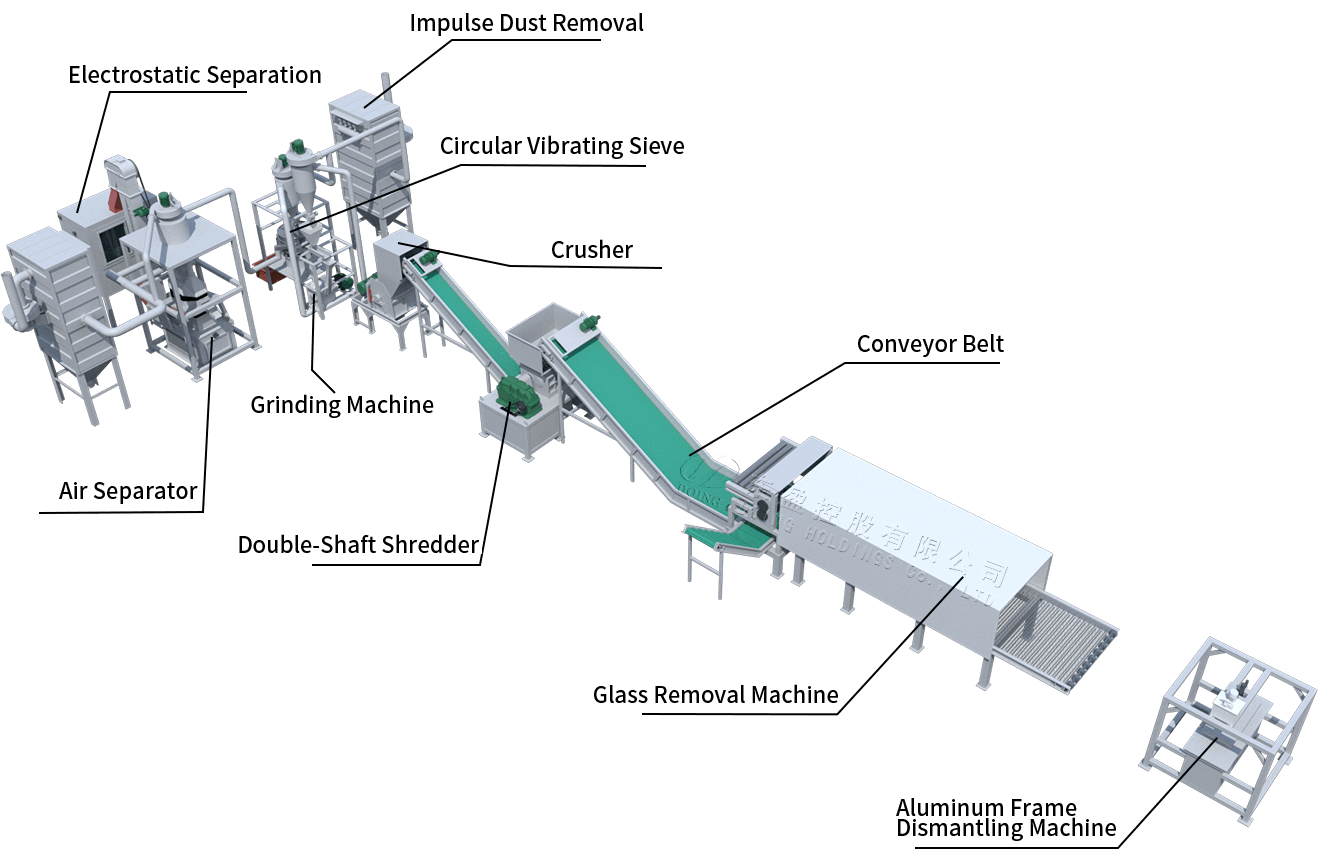

The DOING solar panel recycling machine is designed to recycle retired photovoltaic (PV) panels and solar modules of various sizes. Utilizing advanced physical and mechanical separation technology, it efficiently extracts aluminum frames, glass, silicon, copper, plastic, and other materials.

PLC automatic control and a modular design, ensuring compatibility with PV panels of diverse specifications.

A 95% material recovery rate, maximizing resource reuse.

A fully enclosed, pollution-free process, with a 99% purification rate for exhaust gas and dust, meeting high environmental standards.