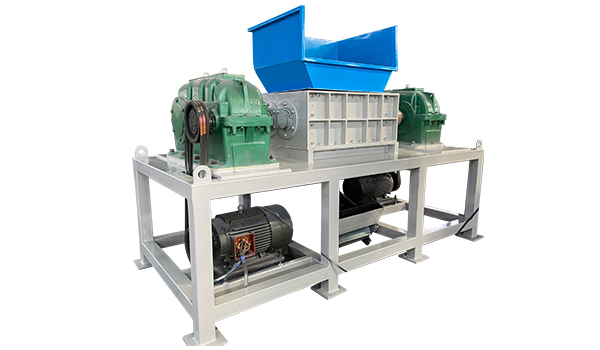

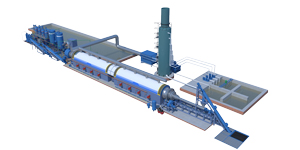

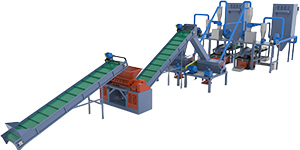

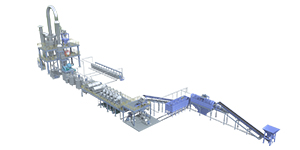

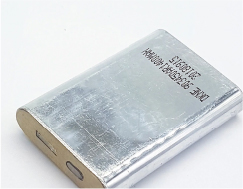

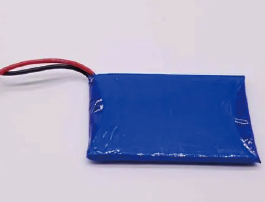

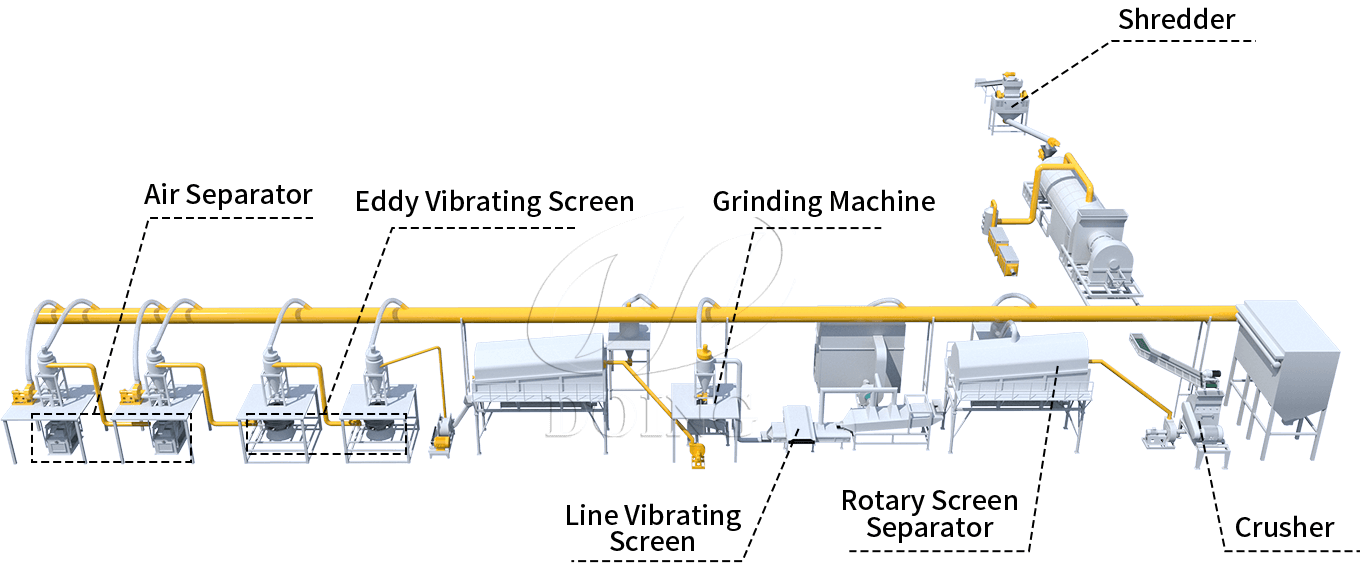

Lithium battery recycling machine is used to recycle and process various waste lithium batteries, including mobile phone lithium batteries, plastic shell batteries, soft-pack lithium batteries, cylindrical lithium batteries, power lithium batteries, battery positive and negative electrode materials, etc. The equipment uses a dry physical mechanical separation process to efficiently separate copper, aluminum, black powder, iron and plastic materials from waste lithium batteries.

The entire lithium battery recycling process is closed without smoke and dust spillage, environmental protection meets standards, and the recycling rate reaches 98%. Through physical recycling methods, it not only reduces resource waste, but also brings good economic benefits.

Before recycling, the used lithium batteries must be discharged. After soaking the used batteries in salt water for 2-3 days, they can be dried or dried naturally. Ensure that the lithium batteries are fully discharged to prevent safety hazards such as fire or explosion.

Before recycling, the used lithium batteries must be discharged. After soaking the used batteries in salt water for 2-3 days, they can be dried or dried naturally. Ensure that the lithium batteries are fully discharged to prevent safety hazards such as fire or explosion.