DOING HOLDINGS

DOING HOLDINGS

A tire pyrolysis plant (also known as a continuous waste tire pyrolysis system) is an integrated setup that transforms discarded tires into useful commodities like pyrolysis fuel, recovered carbon black, steel reinforcement, and syngas. The following is an exhaustive inventory of the core machinery generally found in a complete tire-to-fuel conversion system:

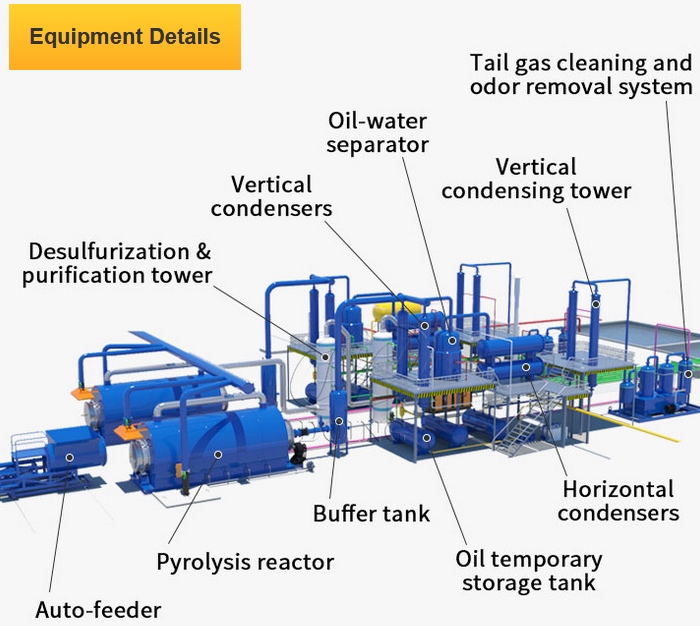

Composition of DOING batch type pyrolysis plant

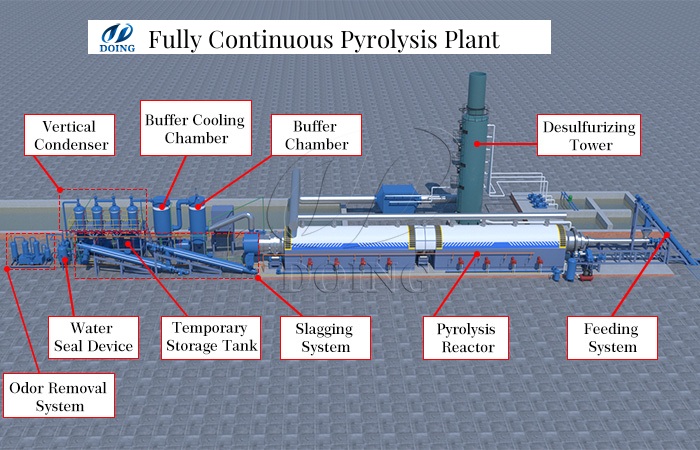

Composition of DOING fully continuous pyrolysis plant

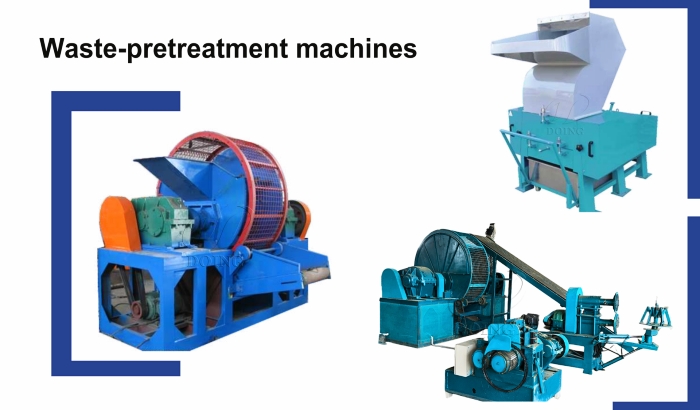

Function: Feedstock Conditioning: Batch-type pyrolysis systems can process whole tires, whereas continuous systems need tires to be pre-processed. This involves sorting, removing bead wires, and cutting tires into uniform pieces to facilitate smooth operation. Pre-extracting steel wires can enhance the pyrolysis process.

Objective: To create a uniform tire-derived feedstock that ensures efficient thermal decomposition and reduces mechanical stress on the equipment.

Key Equipment:

Tire Crusher / Grinding Machine: Processes whole tires into small rubber pieces or fine powder (typically 5-80 mesh). Continuous pyrolysis systems usually require rubber powder sized between 8-16 mesh.

Steel Cord Extractor: Detaches and collects the steel belting from tires before they enter the reactor.

Magnetic Selection Device: Pulls out residual metallic pieces from the shredded rubber material.

Loading Mechanism & Conveyor Feeder: Ensures a consistent and regulated supply of shredded tires into the reactor, particularly crucial for continuous operation models. Batch systems may incorporate an automated loading accessory.

DOING pyrolysis plant raw material preparation unit

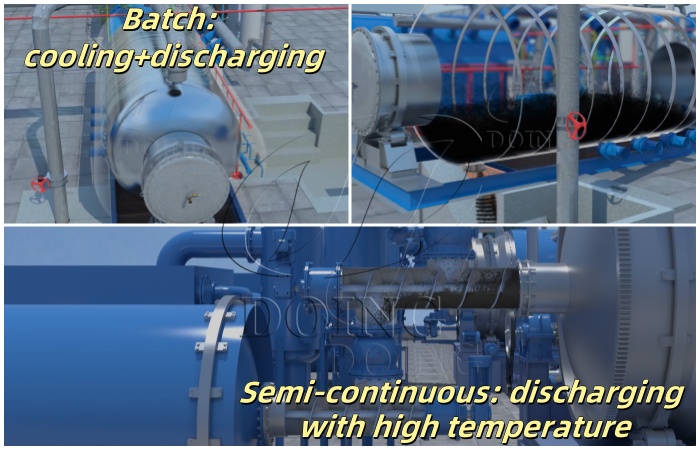

Process: Thermal Cracking: This occurs in a sealed, oxygen-deprived reactor (commonly a horizontal rotary design) heated to between 400°C and 550°C. Heating sources can include external fuels like natural gas or diesel, or internally recycled syngas generated by the process itself for enhanced energy efficiency.

Objective: Serves as the central component where tire polymer chains are broken down into vapor, solid carbon residue, and gas through high-temperature, anaerobic decomposition.

Primary Component: Pyrolysis Reactor

DOING Group employs specially engineered horizontal pyrolysis reactors, which provide significant benefits:

Uninterrupted Operation (Optional): Certain configurations allow for continuous input of material and output of products, boosting overall throughput.

DOING tire pyrolysis plant feeding system

DOING tire pyrolysis plant discharging system

Consistent Thermal Distribution: The rotating mechanism guarantees even exposure of rubber to heat, which optimizes cracking performance and the quality of the resulting fuel.

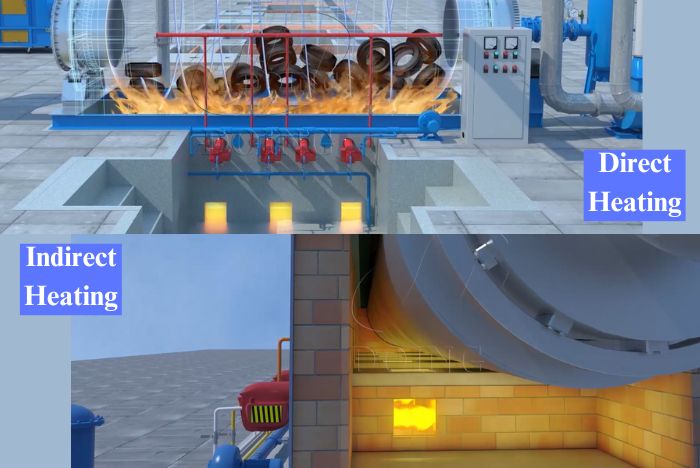

Superior Heat Utilization: The design, whether using direct or indirect heating methods, promotes effective thermal transfer, thereby lowering energy consumption.

DOING tire pyrolysis plant heat utilization

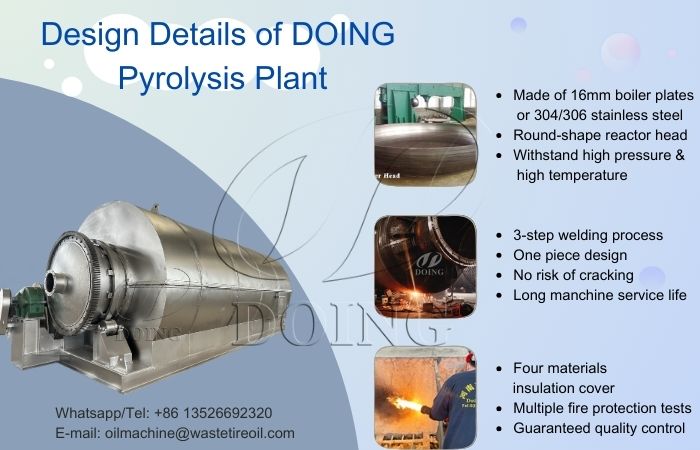

Construction: Fabricated from specialized steel alloys (e.g., Q345R, Q245R) that resist high temperatures and oxidation, and lined with refractory insulation to ensure operational durability and safety.

Design details of DOING tire pyrolysis plant

Process: Vapor Condensation and Fuel Collection: Hot vapors released from the reactor are cooled down through condensers, converting them into liquid pyrolysis oil. The condensation rate generally achieves 85-90%, varying with system design and operational parameters.

Syngas Purification and Reutilization: Gases that do not condense are cleaned and frequently redirected to fuel the reactor.

Objective: Transform gaseous oil vapors into a stable liquid fuel product.

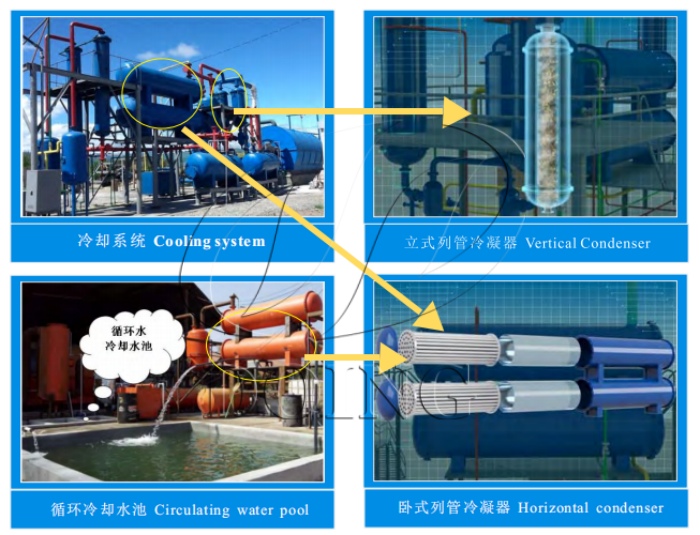

Multi-Stage Cooling Apparatus:Commonly uses a sequence of vertical or horizontal condensers, supported by a closed-loop water cooling circuit. DOING Group's condensation technology is engineered for high recovery rates.

DOING tire pyrolysis plant multi-stage cooling apparatus

Liquid Separation Unit: Divides the condensed liquid into oil and water; the oil is then directed to storage tanks after filtering.

Pressure Reduction System (Optional): Creates a partial vacuum to lower condensation temperatures for some components, potentially increasing fuel output and quality.

Process: Product Management: The produced pyrolysis oil is held in designated tanks. The solid carbon black is gathered and may be processed further; separated steel is cleaned and stored for resale or recycling.

Syngas Recovery and Recycling Setup

Objective: Captures non-condensable gases and reuses them as a primary heat source for the reactor, creating an energy-self-sufficient cycle.

Advantages: Enhances overall energy economy, cuts down on external fuel needs, and minimizes the plant's emission footprint.

DOING tire pyrolysis plant syngas recovery and recycling setup

Pyrolysis Fuel Storage Tanks

Holds the final liquid pyrolysis oil. These tanks are equipped with safety features including leak prevention and static electricity control.

DOING tire pyrolysis plant fuel storage tanks

Carbon Black Treatment Line (Optional)

Equipment: Enclosed carbon black transfer system, carbon black briquetting press.

Purpose: To cool, gather, and potentially refine the carbon black into a marketable product, which may include pelletizing for easier handling and transport.

Steps Involved: Cooling, sieving, grinding or pelletizing (if needed), dust management, and bagging.

Carbon black grinding machine

Carbon black briquetting machine

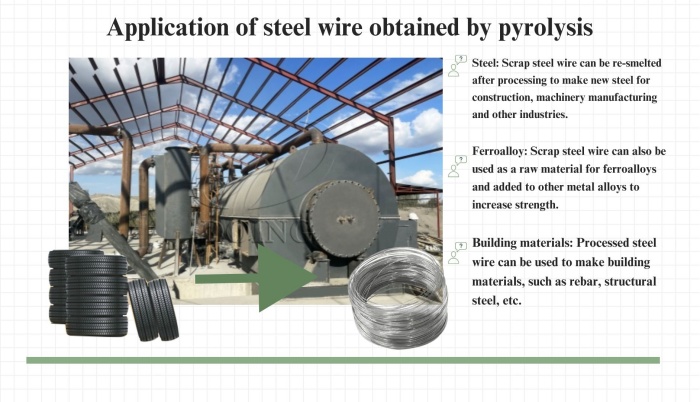

Steel Wire Accumulation System

Gathers and stores the extracted steel wires for disposal or sale.

Application of steel wire obtained by pyrolysis

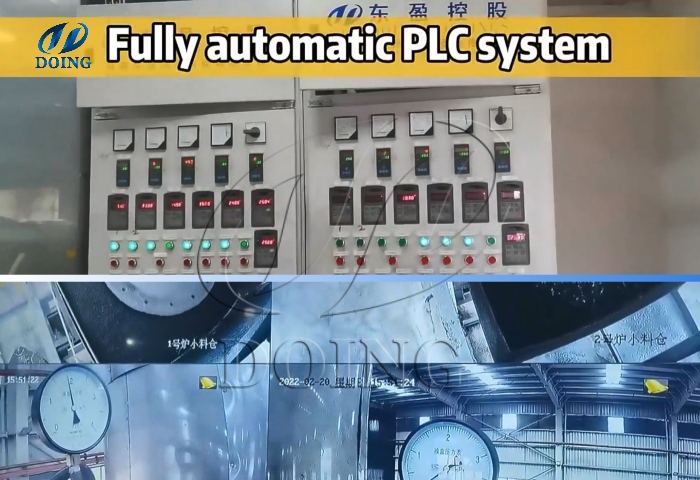

Process: Process Control and Monitoring: A centralized Programmable Logic Controller (PLC) system oversees critical parameters including thermal levels, internal pressure, material feed speed, safety lockouts, and energy usage to maintain stable and reproducible operations.

Central Control Unit / Automated Operation System (Optional)

Core Capabilities: Automated process initiation and shutdown, precise regulation of temperature and pressure, management of feedstock input, safety interlocking, alert systems, operational data recording, and potential for remote oversight.

Components: PLC with a human-machine interface (HMI), various sensors (for temperature, pressure, material level, gas presence), control actuators, safety interlocks, and data communication interfaces.

DOING tire pyrolysis plant fully automatic PLC system

Safety Assurance Devices

Incorporates multiple safeguards such as pressure release valves, emergency shutdown controls, explosion-proof fittings, level detection sensors, and over-temperature warning systems to protect both the machinery and operating personnel.

DOING tire pyrolysis plant safety assurance devices

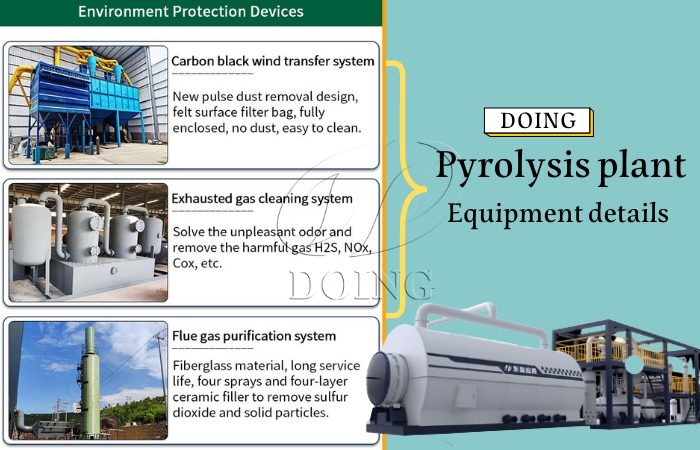

Process: Pollution Mitigation: Exhaust gases are treated to remove particulate matter, sulfur compounds, and other acidic components, with continuous monitoring to ensure compliance with environmental regulations.

Cooling Water Circulation Unit: A recirculating water reservoir supplies cooling water for the condensers and other heat exchange equipment.

DOING tire pyrolysis plant cooling water circulation unit

Flue Gas Treatment System (e.g., Scrubber Tower, Spray Tower):Purifies exhaust gases to meet environmental standards by eliminating sulfur oxides, acidic gases, and fine particles.

Common Configurations:

Alkaline scrubbing for removal of HCl and SOx.

Particulate capture using pulse-jet bag filters.

Adsorption of residual sulfur compounds using activated carbon beds.

DOING tire pyrolysis plant flue gas treatment system

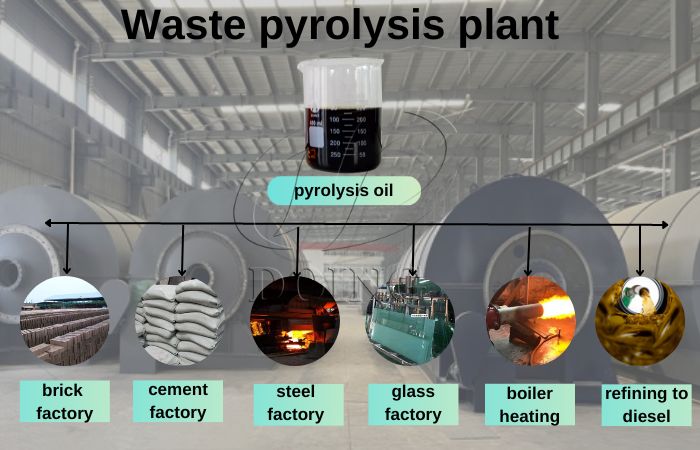

Applications of Pyrolysis Oil:

Industrial Heating Fuel: Serves as a direct replacement for diesel or heavy oil in boilers, steam generators, and other heating applications, offering substantial cost savings.

Process Heating Fuel: Applicable in high-temperature industrial settings like cement kilns, brick manufacturing, and ceramic production.

Applications of tire pyrolysis oil

Further Value Addition

Pyrolysis Oil Distillation Unit: The crude pyrolysis oil can be upgraded through a refining process to produce higher-value diesel and bitumen, thereby expanding market opportunities. This refinement significantly enhances product quality and application scope:

Premium Diesel Alternative: The distilled light fraction exhibits properties and performance comparable to conventional diesel, suitable for direct use in:

Engines: Vehicles, agricultural machinery, power generators, etc. (subject to engine compatibility and local regulations).

Industrial Heating Systems: Can be used as a reliable and efficient alternative to standard diesel.

Marine Fuel: Potential for use as bunker fuel where it meets specific quality standards.

Bitumen Production: The heavier residual fraction can be processed into a key ingredient for paving asphalt, roofing materials, and waterproofing products, supplying a sustainable material to the construction sector.

Chemical Feedstock: Specific distilled fractions may serve as raw materials for producing synthetic rubber, new plastics, dyes, and other specialty chemicals.

Applications of tire pyrolysis oil refined products

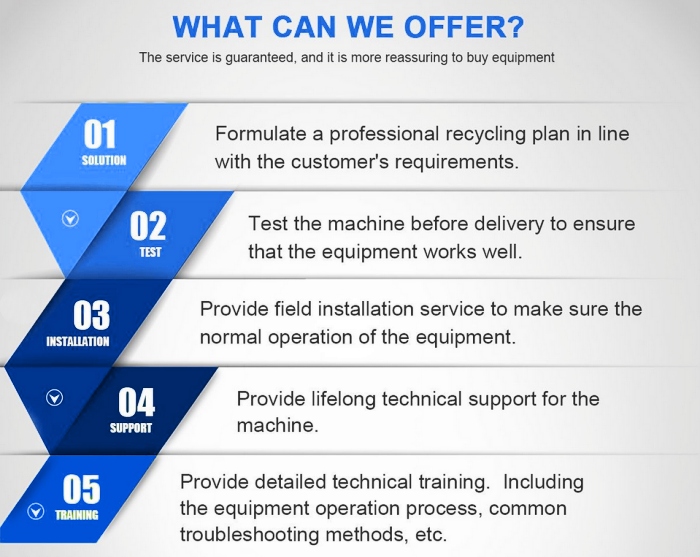

Drawing upon extensive industry presence and deep technical knowledge, DOING Group delivers advanced tire pyrolysis solutions to an international clientele. Our systems are distinguished by their modern engineering, outstanding energy conservation, and strong environmental compliance.

DOING tire pyrolysis plant manufacturer

Should you wish to receive detailed information about our tire pyrolysis plant configurations, gain insights into the operational workflow, technical specifications, or economic viability, DOING Group invites you to get in touch. Our team is ready to offer expert advice and comprehensive support.