DOING HOLDINGS

DOING HOLDINGS

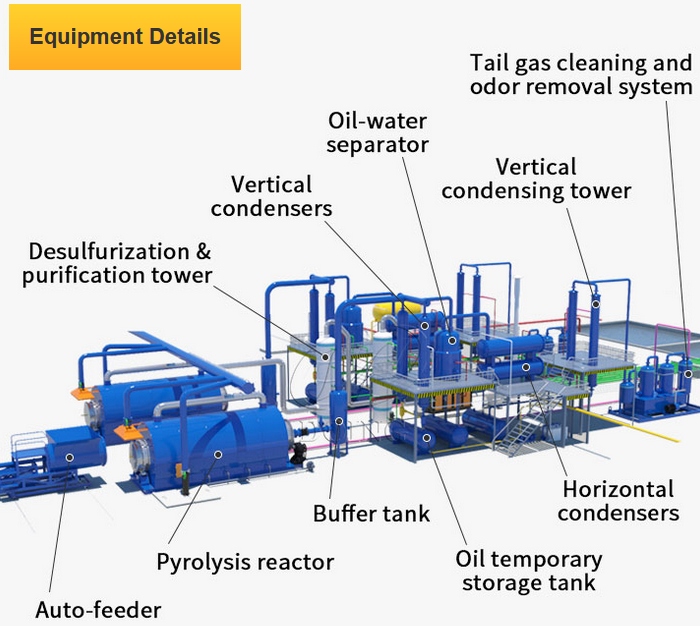

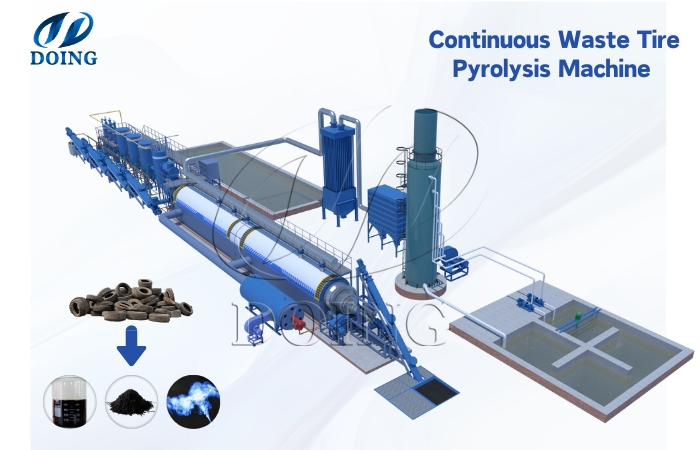

DOING Group is a reputable manufacturer of pyrolysis plants that specialize in converting waste materials into valuable resources through thermal decomposition pyrolysis system process. The pyrolysis plants are designed to process various types of waste, including tires, plastics, and oil sludge, into useful products such as fuel oil, carbon black, residue solid and steel wires.

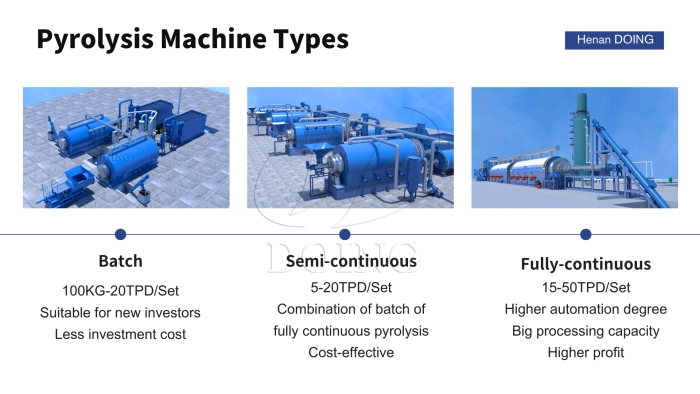

There are three types of pyrolysis system, batch type, semi-continuous type, and fully continuous type each have their own characteristics and are suited to different operational needs. Below is a difference of these three types of pyrolysis systems based on various factors:

DOING three types of pyrolysis system

DOING three types of pyrolysis system

Operation Mode

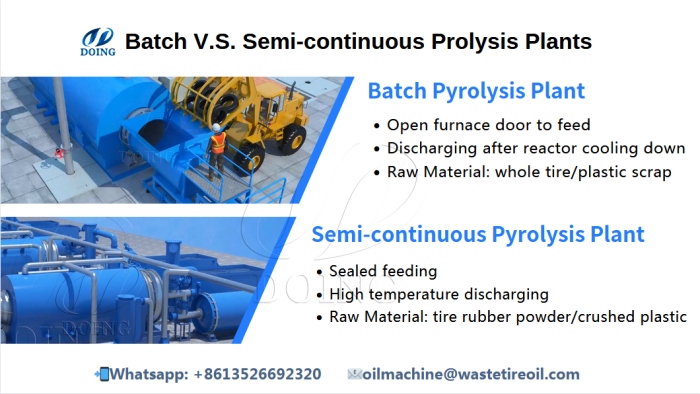

1.Batch Type Pyrolysis system:

Operation: Involves loading the reactor with feedstock, heating it until the pyrolysis process is complete, cooling down the reactor, unloading the products, and then reloading for another cycle.

Frequency: Requires downtime between batches for loading/unloading and cooling/heating cycles.

Details of DOING batch type pyrolysis system

Details of DOING batch type pyrolysis system

2.Semi-Continuous Pyrolysis system:

Operation: Allows for almost continuous operation by having multiple reactors or a system where new material can be fed into the reactor while the process continues, at least you can do 3 batches within two days compared with batch type production pyrolysis system.

Frequency: Offers higher throughput than batch systems.

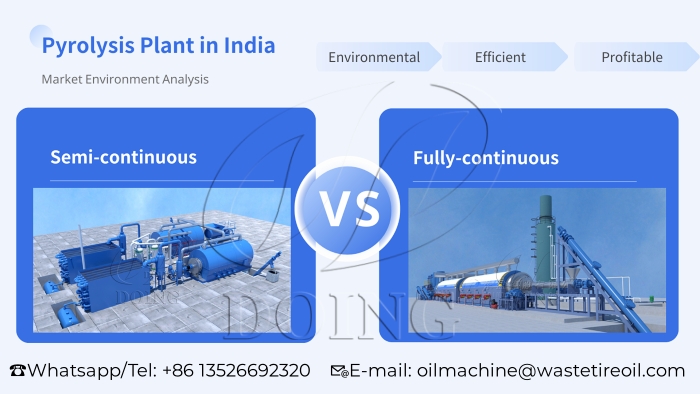

Semi-continuous and continuous pyrolysis systems difference

Semi-continuous and continuous pyrolysis systems difference

3.Fully Continuous Pyrolysis system:

Operation: Designed for uninterrupted operation, where raw materials are continuously fed into the reactor, and products are continuously discharged without needing to stop the process.

Frequency: Provides the highest level of production efficiency among the three types, suitable for large-scale operations.

Throughput and Efficiency

1.Batch Type Pyrolysis system: Due to its batch nature, its daily processing capacity is generally lower than the other two types, ranging from 100 kg to 15 tonnes.

Batch continuous pyrolysis systems difference

Batch continuous pyrolysis systems difference

2.Semi-Continuous Pyrolysis system: Offers increased throughput over batch systems, making it more efficient for medium-scale operations.

3.Fully Continuous Pyrolysis system: Achieves the highest throughput and is most efficient for large-scale industrial applications.

DOING continuous type pyrolysis system

DOING continuous type pyrolysis system

By understanding the differences between these systems, you can select the one that aligns with your operational goals and maximizes your waste-to-fuel production efficiency. Whether you want to start a small scale or big scale waste to fuel project, please feel free to contact DOING, DOING will provide you with the most suitable solution for you.