DOING HOLDINGS

DOING HOLDINGS

Waste oil sludge, generated during oil storage and refining, contains significant oil components and poses serious environmental and economic challenges. Effective treatment is crucial for resource recovery, pollution control, and sustainable development. Below is an organized overview of the primary treatment techniques:

Physical/chemical methods are commonly used for pre-treatment to reduce waste oil sludge volume and improve its characteristics:

Dewatering: Separates water from waste oil sludge via centrifugation or filtration, significantly reducing volume.

Chemical Washing: Uses surfactants or acids to extract oil, improving oil sludge quality for subsequent processing.

Adsorption: Employs activated carbon or clay to absorb oil, further purifying the waste oil sludge.

These methods are often used as pre-treatment steps before pyrolysis, refining, or landfilling. However, they may generate secondary waste and have limited effectiveness on high-viscosity waste oil sludge.

Incineration involves high-temperature combustion of waste oil sludge to generate heat energy. It rapidly reduces waste volume and recovers energy. But it may release pollutants like dioxins if not properly controlled and is less suitable for low-calorific value oil sludge.

Landfilling disposes of stabilized waste oil sludge in approved sites. It is simple and low-cost but poses long-term environmental risks such as groundwater contamination and faces regulatory restrictions.

Bio-remediation uses microorganisms to break down oil components. It is environmentally friendly and cost-effective for low-concentration sludge but has slower decomposition rates and is less effective on high-viscosity oil sludge.

Refining converts thin or liquid waste oil sludge into high-value products like diesel through distillation, hydrogenation, or catalytic cracking. It produces high-quality fuels but requires strict pre-treatment and involves complex chemical processes.

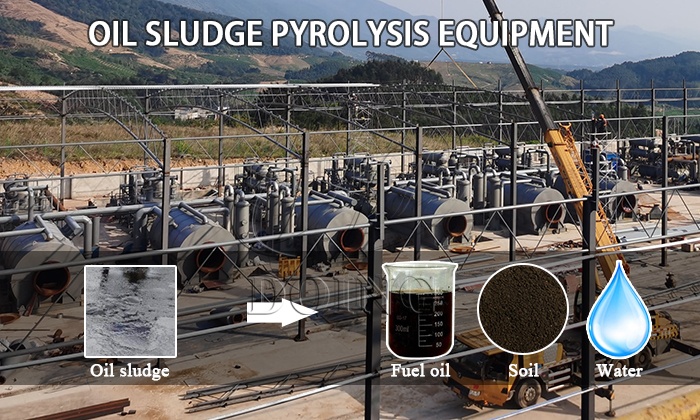

Waste oil sludge refining plant

Pyrolysis stands out as an advanced and promising method. It heats waste oil sludge in the absence of oxygen, decomposing it into fuel oil, solid residue (soil), and syngas. The main application of oil products produced by our waste pyrolysis plant is the fuel oil that is widely used for industrial and commercial purposes. For example, the fuel oil can be used as heating fuel for boiler factory, cement factory, glass factory and power factory,etc.The second product of our waste oil sludge pyrolysis plant is soil. The 3rd product of our waste oil sludge pyrolysis plant is syn-gas and the main component of the syn-gas is bio-gas (CH4), so we can not condense and store this gases. We use this gases as the heating energy for the waste oil sludge pyrolysis plant or oil refinery plant and we can use exceed gases for other heating application. Pyrolysis effectively converts waste into resources, reduces environmental risks, and has relatively few pollutants. However, it requires high initial investment and specialized operational management.

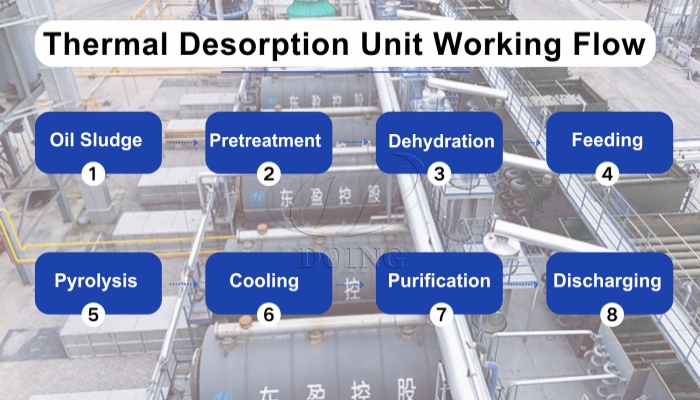

Waste oil sludge pyrolysis process

Waste oil sludge pyrolysis products

In conclusion, selecting the appropriate treatment method depends on waste oil sludge characteristics, treatment goals, economic benefits, and environmental impacts. Pyrolysis technology, with its resource recovery and environmental advantages, is expected to play a significant role in waste oil sludge treatment. Henan DOING Group has been focusing on energy environmental protection equipment for more than fourteen years. It is a professional manufacturing enterprise integrating development, design, production, sales, installation and after-sales service. For waste oil sludge treatment, we have corresponding patented technologies and multiple successful oil sludge pyrolysis plant operation projects, which can effectively solve problems such as coking and wall sticking, and have assisted many customers in achieving efficient waste oil sludge resource treatment.

DOING waste oil sludge pyrolysis plant manufacturer

If you want to know more about how to proceed waste oil sludge in a sustainable treatment way, please feel free to contact us.