DOING HOLDINGS

DOING HOLDINGS

Henan Jinrui Food Engineering Co., Ltd is located in Zhengzhou City, Henan Province of China, It is a professional company that is dedicated to designing, manufacturing, installing, and commissioning cassava processing equipment. We have our own engineering team and manufacturing factory, which can provide the best solution and most competitive price. The article will briefly introduce our cassava processing equipment.

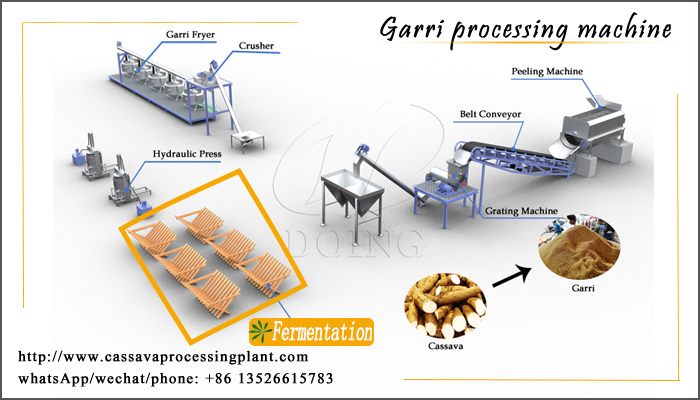

Garri production line

We can provide complete equipment for garri production, including dry sieve cleaning equipment, paddle washer, peeling equipment, grating equipment, hydraulic presser equipment, garri fryer, vibration sieve, and packaging equipment. Both small scale garri equipment and complete garri production line are available. Capacity ranges from 1tpd to 50tpd garri output.

garri processing line

garri processing line

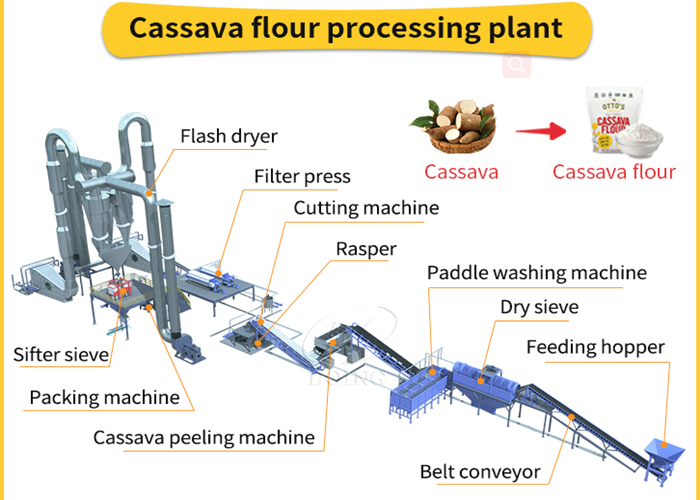

Cassava flour production line

Cassava flour is produced from fresh cassava roots by means of raw cassava cleaning, washing, peeling, crushing, dehydrating, drying, fine milling, and sieving. Henan Jinrui company can provide complete cassava flour production line from beginning to end. equipment we can provide are feeding hopper, belt conveyor, dry sieve, paddle washer, sand roller peeling equipment, cutting equipment and rasper, de-sander, plate-and-frame filter press, flash dryer, fine miller, sifter, and packaging equipment. Capacity ranges from 2t/h to 40t/h cassava tubers input.

cassva flour processing line

cassva flour processing line

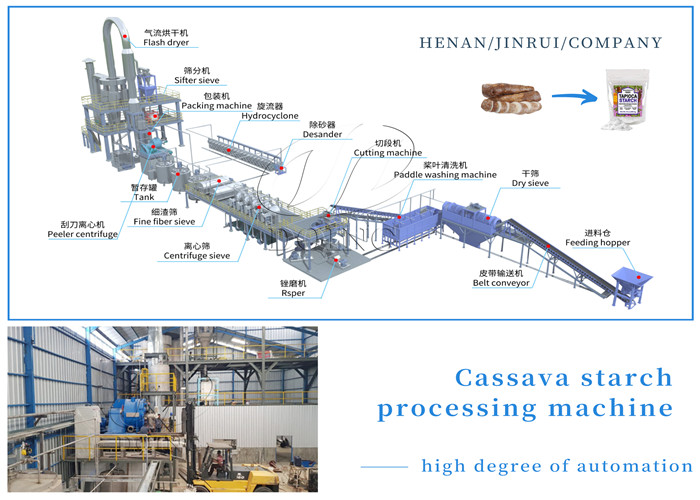

Cassava starch production line

The cassava starch production line consists of raw cassava cleaning, cleaned tubers crushing, fiber separation, de-sanding, protein and cell liquids removal, starch slurry dewatering, starch drying, sieving, and packaging. The main equipment supplied by Henan Jinrui includes dry sieve, paddle washer, cutting equipment, rasper, centrifuge sieve, de-sander, hydrocyclone station, vacuum filter, flash dryer, sifter, and packer. Capacity ranges from 2t/h to 60t/h cassava root input.

cassava starch processing line

cassava starch processing line

Cassava chipping line

The full set of cassava chipping lines consists of cassava feeding hopper, belt conveyor, dry sieve, cassava chipping equipment, and non-standard connecting parts. Raw cassava roots will be put into feeding hopper first, and then transported by belt conveyor to the dry sieve equipment. A dry sieve equipment can remove impurities attached to the surface of raw cassava. Finally cleaned cassava will go into the chipper equipment for the slicing process. The main equipment are feeding hopper, belt conveyor, dry sieve, and chippers. The capacity of the plant is 15-20t/h cassava input.

cassava chips making line

cassava chips making line

Equipment for other cassava products

Apart from the above cassava processing equipment, Henan Jinrui company also provide equipment for other cassava product like bammy, attieke, fufu, etc.

If you have any requirements for cassava processing equipment, feel free to contact us at any time. The Cassava processing equipment catalog and product list can be sent to you via email address.