DOING HOLDINGS

DOING HOLDINGS

Home>News>Industry News>Can Wood Chips Be Carbonized? High-efficiency continuous carbonization solution

Home>News>Industry News>Can Wood Chips Be Carbonized? High-efficiency continuous carbonization solution

Large quantities of wood chips generated from wood processing are often treated as waste, which not only wastes resources but may also cause environmental pollution. However, wood chips can be converted into high-value biochar through professional wood chips carbonization equipment, enabling the recycling of resources.

In terms of raw material characteristics, wood chips are rich in organic components such as cellulose and lignin, making them excellent materials for wood chips carbonization reactions. In a high-temperature, oxygen-deficient environment, moisture and volatile substances in wood chips gradually release, and the organic components undergo pyrolysis, ultimately forming biochar with a stable structure. Compared to other biomass raw materials, wood chips have a loose texture and large surface area, allowing for more uniform heating and easier control of the wood chips carbonization process, resulting in stable-quality carbon products.

Wood chips carbon products

Wood chips carbon products

The wood chips carbonization of wood chips offers both environmental and economic benefits. Environmentally, carbonizing wood chips instead of using traditional incineration methods can reduce harmful gas emissions and minimize air pollution. Meanwhile, the biochar produced can be used for soil improvement, enhancing water and nutrient retention, reducing the need for chemical fertilizers, and supporting green agricultural development. Economically, wood chips are widely available and low-cost, while the carbonized products have diverse applications. They can be used as civilian fuels such as barbecue charcoal or heating charcoal, processed into activated carbon for water purification or air filtration, or serve as raw materials for industrial production, generating significant economic benefits.

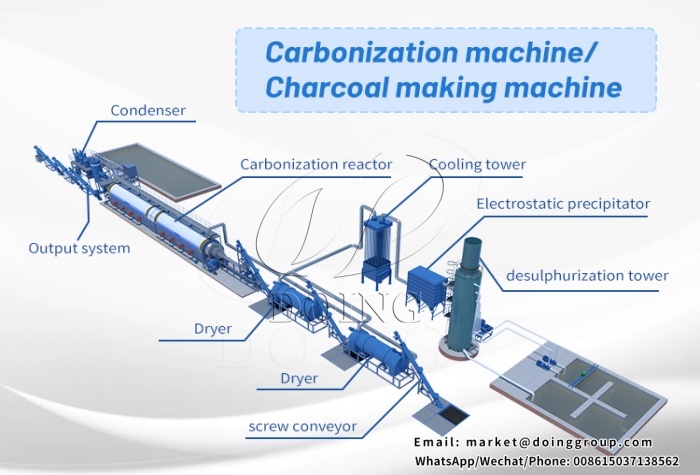

Achieving efficient carbonization of wood chips relies on professional wood chips carbonization equipment. DOING continuous carbonization furnace, with their numerous advantages, are an ideal choice for wood chip carbonization. Traditional earthen kiln carbonization methods are inefficient, uneven, and suffer from high energy consumption and pollution, making them unsuitable for modern production needs. In contrast, continuous carbonization furnaces feature automated designs, enabling continuous feeding, carbonization, and discharging of wood chips, significantly improving production efficiency and making them suitable for large-scale industrial production.

Wood chip continuous carbonization equipment

Wood chip continuous carbonization equipment

However, there are key considerations for wood chip carbonization process. First, pretreatment of wood chips is necessary to control moisture content, typically kept within 15%, to avoid reduced carbonization efficiency and quality due to excessive moisture. Second, carbonization parameters such as temperature, time, and feeding speed should be adjusted according to the characteristics of the wood chips to ensure optimal carbonization results.

The intelligent temperature control system equipped in continuous carbonization furnaces allows precise regulation of the internal temperature, typically set between 400-800°C, ensuring thorough carbonization of wood chips and producing charcoal with high fixed carbon content and stable calorific value. Additionally, the equipment boasts excellent sealing performance, effectively isolating air to prevent combustion during carbonization and ensuring the carbonization reaction proceeds smoothly. Moreover, continuous carbonization furnaces are equipped with efficient environmental treatment devices that recover and purify smoke and tar generated during carbonization. This not only reduces environmental pollution but also allows the recycled combustible gas to be reused as fuel, lowering production costs.

Doing biomass continuous carbonization furnace

Doing biomass continuous carbonization furnace

Wood chips can not only be carbonized but are also a highly promising carbonization raw material. Choosing a suitable continuous carbonization furnace can make wood chip carbonization efficient, environmentally friendly, and economical. As a professional manufacturer of continuous carbonization furnaces, DOING has extensive experience in equipment development and production and can provide customized carbonization solutions based on the characteristics of wood chips. If you would like to learn more about the specific process of wood chip carbonization or need reliable carbonization equipment(including the wood charcal compressor briquettes machine), please feel free to contact us for consultation. We will provide you with professional technical support and detailed quotations!