DOING HOLDINGS

DOING HOLDINGS

Home>News>Industry News>Differences Between Calcination and Pyrolysis: Pyrolysis Solution is More Effective for Waste Recycling

Home>News>Industry News>Differences Between Calcination and Pyrolysis: Pyrolysis Solution is More Effective for Waste Recycling

When considering thermal treatment for waste materials, you might encounter terms like "calcination" and "pyrolysis." While both involve heating materials, they are fundamentally different processes with distinct objectives and outcomes. Understanding these differences is crucial for selecting the most effective technology for your specific waste treatment requirements.

Calcination is a thermal treatment process applied to inorganic materials, such as minerals or ores, to drive off volatile components or induce chemical changes. It typically involves heating the material in the presence of air or oxygen, leading to decomposition or phase transformation without melting the substance.

The main purpose of calcination is to purify or stabilize the material for further use. For instance, in the lime industry, limestone (CaCO₃) is calcined at around 900-1000°C to produce quicklime (CaO) and carbon dioxide gas. This process is essential in industries like cement production, metallurgy, and ceramics, where the goal is to create simpler, more reactive compounds. Calcination often results in a solid residue, such as oxides or ashes, with reduced moisture and impurities. It's an energy-efficient method for materials that don't require complete breakdown, but it can generate emissions like CO₂, requiring proper control in modern setups.

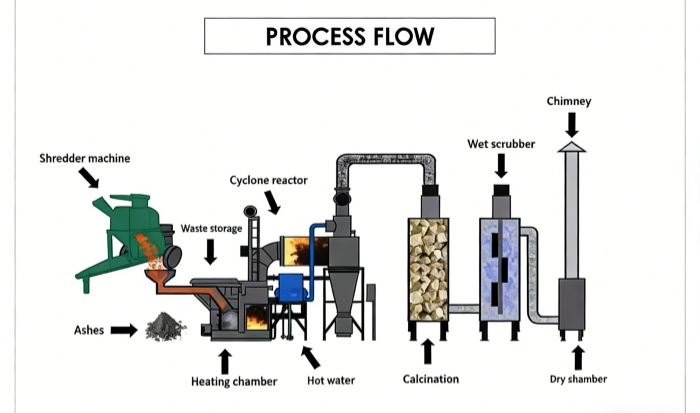

In waste processing contexts, calcination-like processes (sometimes overlapping with incineration) are used to convert general waste into inert ashes, minimizing volume for landfill disposal. However, this approach focuses on destruction rather than resource recovery.

Calcination process

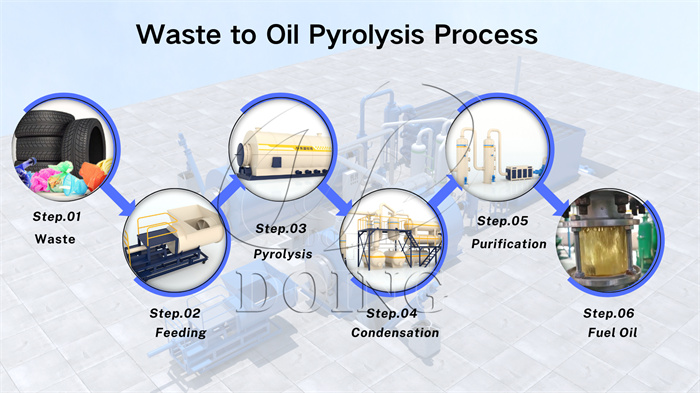

Pyrolysis is a thermochemical process that decomposes organic materials—such as plastics, or tires—at elevated temperatures in the absence of oxygen. This oxygen-free environment prevents combustion, allowing the material to break down into smaller molecules through thermal cracking.

The primary aim of pyrolysis is to convert waste into usable products, including pyrolysis oil, carbon black, and syngas. Temperatures typically range from 300-500°C, depending on the feedstock and desired output. For example, in tire recycling, pyrolysis can yield up to 45% oil, 30% carbon black, and 10% gas from a ton of waste tires.

Pyrolysis is widely applied in waste management and renewable energy. It's particularly valuable for handling mixed general waste, as it handles diverse feedstocks without the need for sorting and produces fewer emissions than open burning. The process operates in a controlled system, capturing byproducts for sale or reuse, which supports circular economy principles.

Waste pyrolysis to oil process

To highlight the distinctions more clearly, here's a comparison table:

| Comparison Dimension | Calcination | Pyrolysis |

| Atmosphere | Oxygen or limited air | Oxygen-free |

| Temperature Range | Generally higher (500–1000°C) | Wider range (300–500°C ) |

| Main Objective | To change the chemical structure of the material and obtain stable oxides/inorganic substances | To decompose large organic molecules into useful products |

| Typical Raw Materials | Inorganic minerals, ores | Organic waste (plastics, rubber, oil sludge, etc.) |

| Main Products | Solids (metal oxides, ash) + flue gas (CO₂, water vapor, etc.) | Fuel oil, carbon black, combustible synthesis gas |

| Oxidation Reaction | May occur, some materials are oxidized | Basically no oxidation occurs, mainly cracking and recombination reactions |

| Energy Recovery | Usually not the main focus, some heat may be recovered | One of the core objectives, products can be directly used as energy |

| Risk of Secondary Pollution | May produce dust and acidic gases (if raw materials contain S/Cl) | Closed system throughout, low amount of waste gas produced, easy to treat; but requires standardized management |

| Economic Drivers | Production of industrial raw materials (e.g., quicklime) | Resource utilization of waste, generating sales revenue (selling fuel oil, carbon black) |

For processing ordinary waste (such as household waste, industrial waste, or mixed organic matter), pyrolysis offers several advantages over calcination:

Resource Recovery:

Calcination processes organic matter at high temperatures in the presence of air, resulting in inert mineral residue ash and flue gas as the main products. Most of the chemical energy contained in the organic matter is released as heat. While it can reduce waste volume, resources are not recovered.

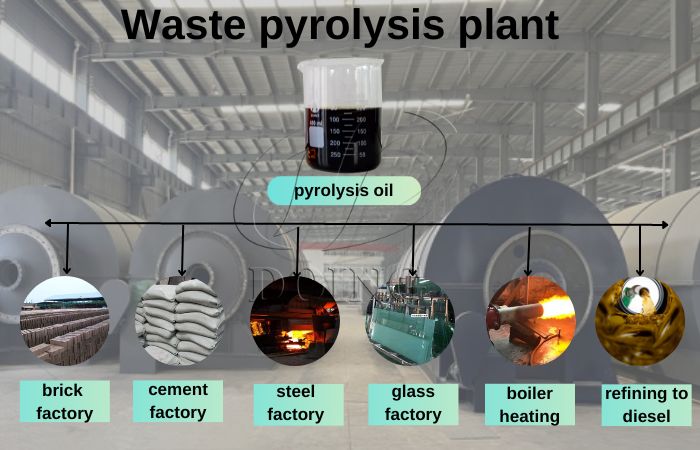

However, pyrolysis effectively decomposes organic components into valuable resources:

Pyrolysis oil: Can be used as fuel for industrial boilers or further refined into higher-value diesel fuel.

Applications of pyrolysis oil

Syngas: A mixture of hydrogen and carbon monoxide produced during pyrolysis, which can be directly recovered and used as heating fuel for the pyrolysis equipment.

DOING pyrolysis equipment syngas recycling system

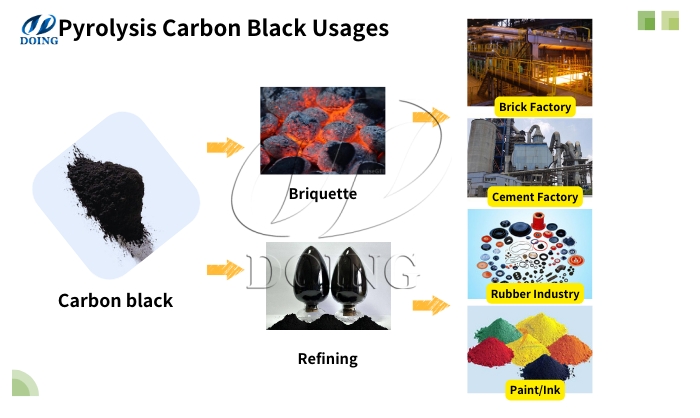

Carbon black: Can be pressed into pellets for combustion or finely ground for use in tires, pigments, etc.

Pyrolysis carbon black usages

Environmental Benefits:

If not handled properly, calcination can easily produce harmful gases such as dioxins, sulfur oxides, and nitrogen oxides, requiring high-level exhaust gas treatment.

Because it operates in an oxygen-free environment, pyrolysis avoids the production of harmful byproducts common in combustion processes (such as dioxins and furans). The emissions from pyrolysis are generally cleaner and easier to treat.

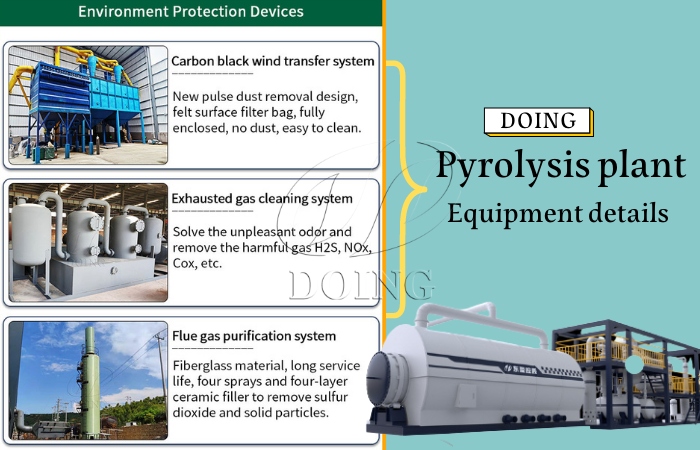

DOING pyrolysis plant environment protection devices

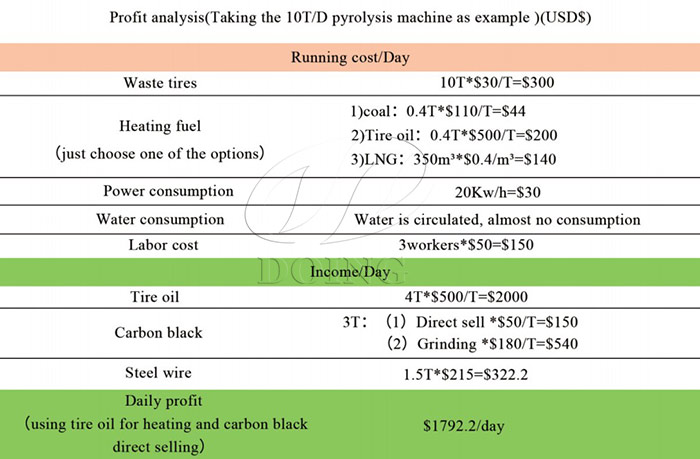

Energy and Economics:

When processing general waste, calcination only uses organic matter as "fuel," and the energy is utilized once in the form of heat, without achieving layered resource recovery, resulting in relatively limited economic benefits.

The syngas and pyrolysis oil produced by pyrolysis can be used to power the pyrolysis process itself, making it more energy-efficient. The resulting pyrolysis oil and carbon black can be sold as commodities, improving the project's economic return.

Processing Mixed Waste:

Ordinary waste is inherently heterogeneous. Pyrolysis is well-suited for processing this mixture, breaking down plastics, organic matter, and other components into their constituent parts to obtain valuable products. While calcination is effective for specific inorganic materials, it is not designed for this complex organic decomposition.

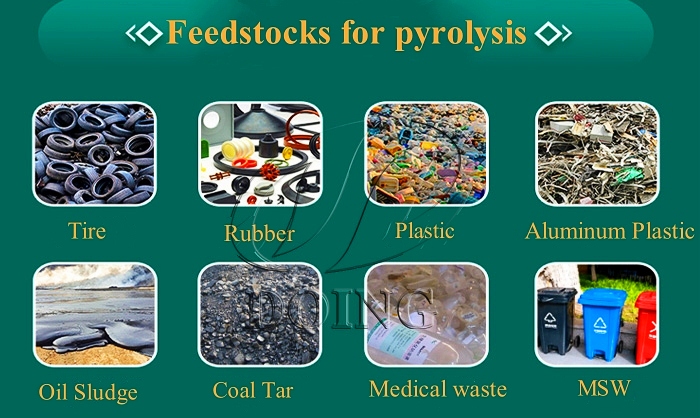

Pyrolysis equipment feedstocks

In short, if your "waste management" inquiry is about efficient waste reduction with added value, pyrolysis provides a balanced method that addresses both environmental compliance and economic viability.

If you are exploring options for general waste treatment and are interested in a technology that can recover valuable products, we invite you to learn more about the capabilities of DOING Company pyrolysis solutions.