DOING HOLDINGS

DOING HOLDINGS

Home>News>Industry News>Introduction of the professional methods and equipment of palm oil production

Home>News>Industry News>Introduction of the professional methods and equipment of palm oil production

All the time, the professional methods of palm oil production is considered to be the pressing method used in Malaysian large scale palm oil mill plant, which includes ten processes from palm fruit reception to palm kernel recovery. DOING HOLDINGS -- Henan Glory Company engineers researched the whole process and equipment of palm oil production, designed 1-2tph, 5tph, 10tph small scale fully automatic palm oil production line, which are very hot sale in many countries, especially in Africa.

1-2tph palm oil processing equipment

1-2tph palm oil processing equipment

And according to the different needs of customers, Henan Glory Company can provide five types of palm oil production equipment for them from simple type to large scale. Below I will introduce the equipment of palm oil production one by one for you.

There are two kinds fo palm oil presser: 500kg/h single screw palm oil presser and double screw palm oil presser with 1tph, 5tph, 10tph,15tph. If you only want to buy a palm oil presser to improve the oil yield rate, you can choose the suitable one for you. The single screw palm oil presser is cheaper, but the double screw palm oil presser is more automatic.

Single screw and double screw palm oil presser

Single screw and double screw palm oil presser

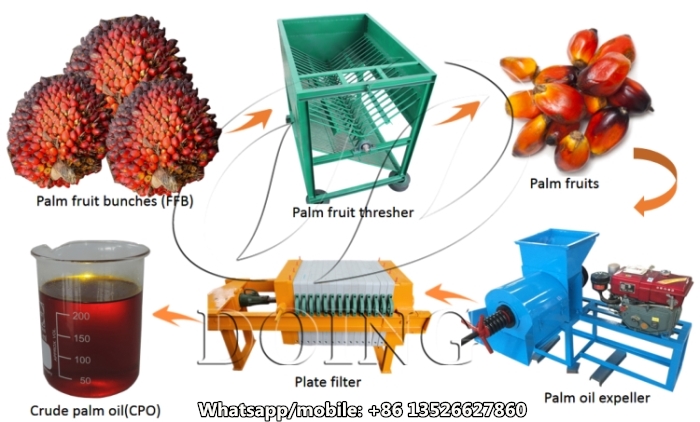

Simple production line of palm oil production equipment includes simple palm fruit thresher, palm oil presser and plate oil filter. It needs workers to operate, but the production efficiency will improve a lot than that of traditional method. As for the palm oil presser, you can choose suitable one based on your budget.

Simple production line of palm oil production equipment

Simple production line of palm oil production equipment

1-2tph complete production line of palm oil production equipment contains conveyor, small sterilizer, drum-type thresher, digester, double screw palm oil presser, vibrating screen, clarification tank, plate oil filter and vacuum drying system. If you also want to process palm kernel, we have fiber separator, palm kernel and shell cracking and separating equipment, palm kernel oil presser, etc.

5tph automatic production line of palm oil production equipment has conveyor, vertical sterilizer, drum-type thresher, digester, double screw palm oil presser, vibrating screen, clarification tank, plate oil filter and vacuum drying system. The sterilizer is different from that in 1-2tph complete production line and the size of equipment will be larger.

Above 10tph medium and large scale production line of palm oil production equipment is the same to that used in Malaysian large scale palm oil mill plant, which includes 9 processing stations: Raw material reception station, sterilization station, threshing station, digesting & pressing station, oil clarification station, oil storage tanks, kernel recovery station, boiler station and water treatment station. As for the equipment, it will be more and very complicated. We also have 3D animation, which you can watch to learn more about it.

After learn about different types of palm oil production equipment, do you have a satisfied one? If you want to know more about the professional methods of palm oil production, you can contact us. Our sales and engineers will explain it for you in detail, and give you a best suggestion on choosing equipment for palm oil production.